|

High

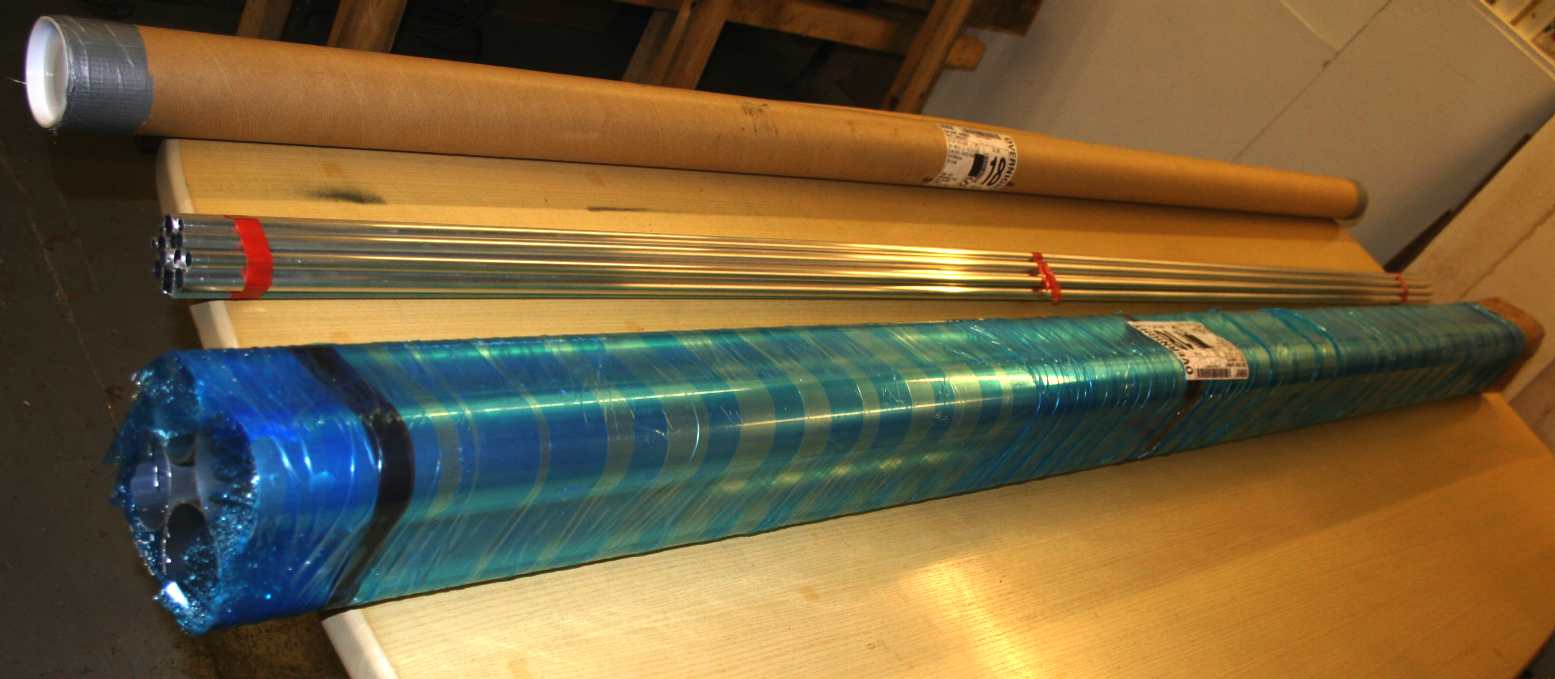

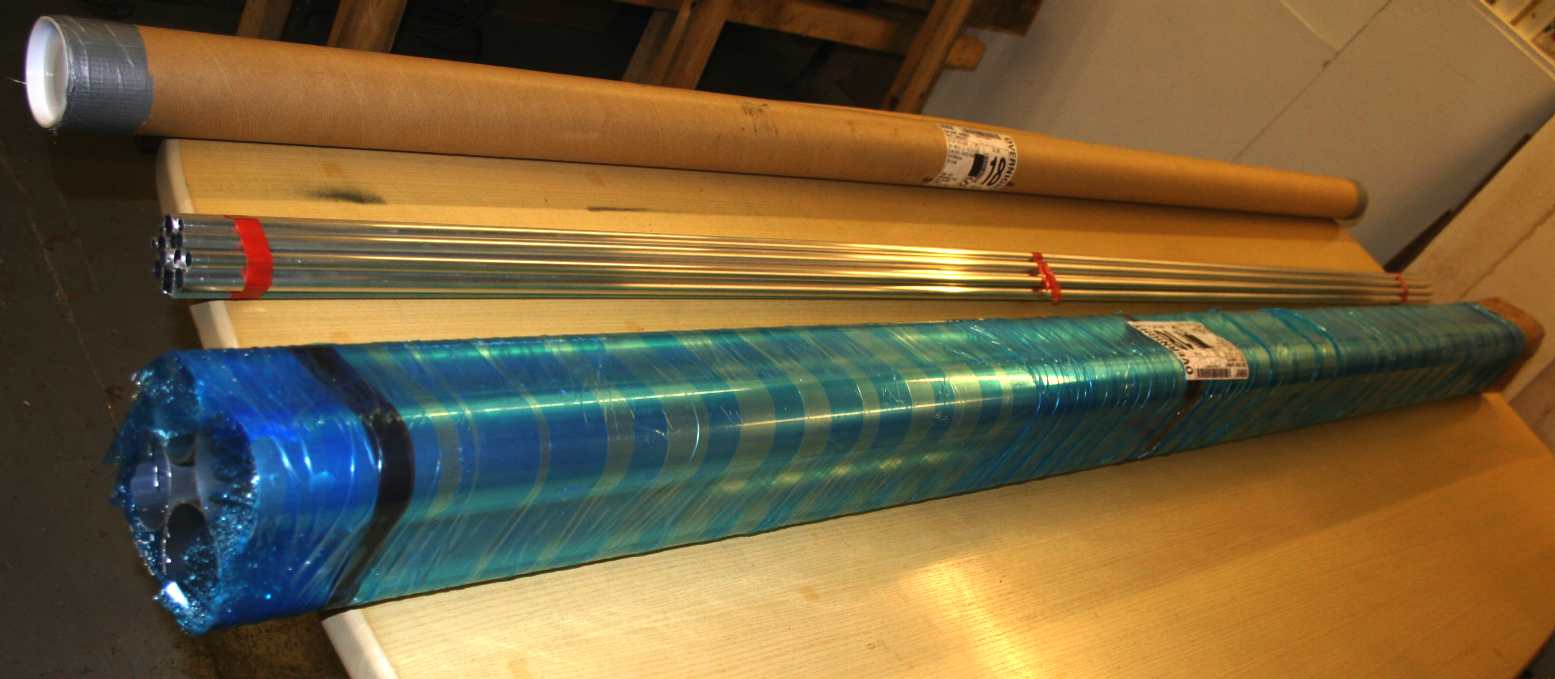

quality aluminium demands high quality packaging. Aluminium Warehouse did us

proud. The 16g medium diameter tubing was supplied as shown, with the smaller

and one longer 5.0m length tube (not shown) coming in the cardboard tubes. The

1mm sheet alloy (not shown) was also protectively sandwiched between two 8' x

4' timber pallets. Apart from the expense of the pallets, AWs products are

great value for money. When ordering sheet, buy as much as you need for

forward works, to spread the pallet cost.

ALUMINIUM

AS A BOAT BUILDING MATERIAL We've

now got a solid Jig to work from. The full size vessel will be built of 5383

alloy, commonly known as Sealium, from Pechiney (the inventors). The models we

are fabricating are to be built from more modest alloys, because they do not

have ten years of life at sea ahead of them - and we are on a tight

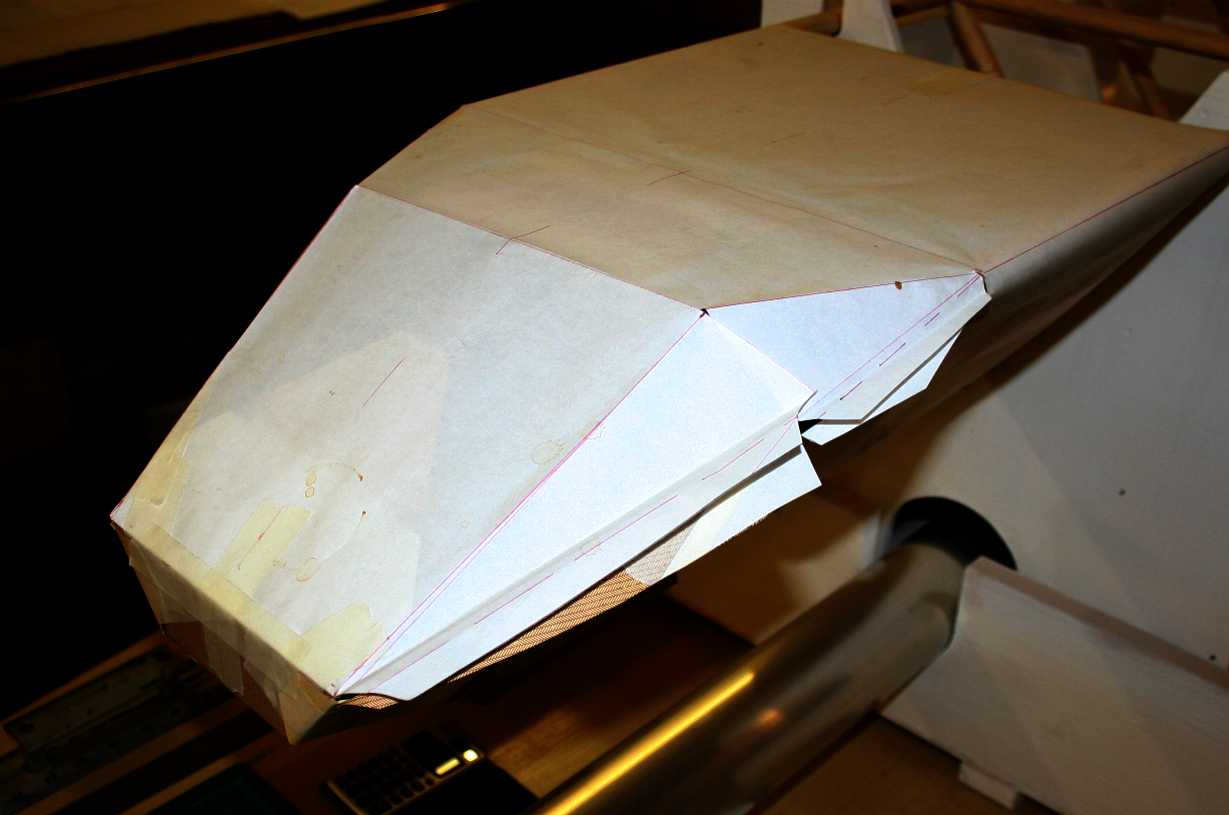

budget. DEVELOPMENT Though

we are building an advanced robot ship, you may have noticed that the model

development has been almost exclusively hand crafted. Yes, okay, from computer

generated drawings, but those in turn came from hand drawings. The boat building

craft is still alive. Having said that, the full size vessel will more than

likely be assembled from a water-jet cut list of parts. On the other hand,

construction at this scale is a useful dry run that will mean that this design

could be built in any reasonably equipped boat yard anywhere in the world. As

the aluminium developments are cut and shaped, we will include them on this

page. At the moment we are converting the computer drawings to 1/20th scale

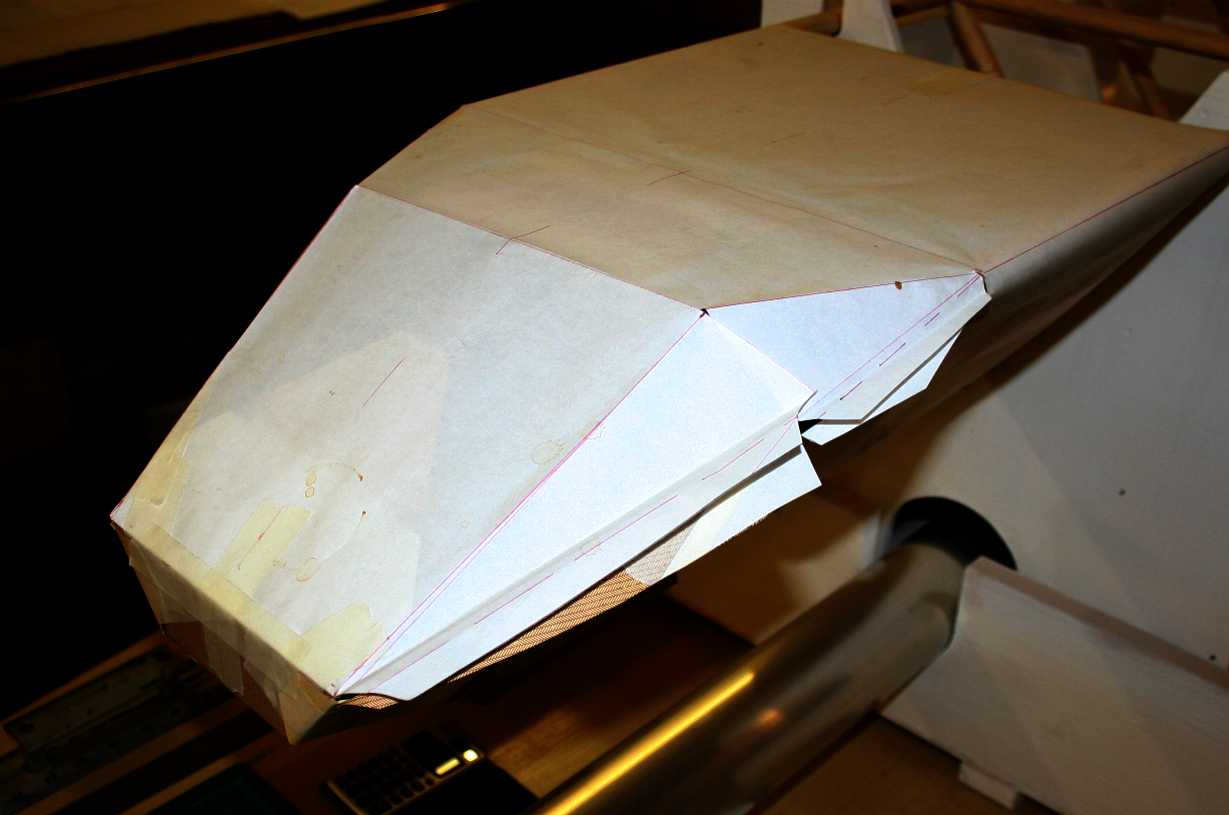

loftings. We are also test folding the developments in paper, before committing

to cutting any aluminium - as you can see from the pictures below. If it works

in paper it will work in aluminium. We have budgeted for only four sheets of 2m

x 1m aluminium, which is for three models. It is going to be tight.

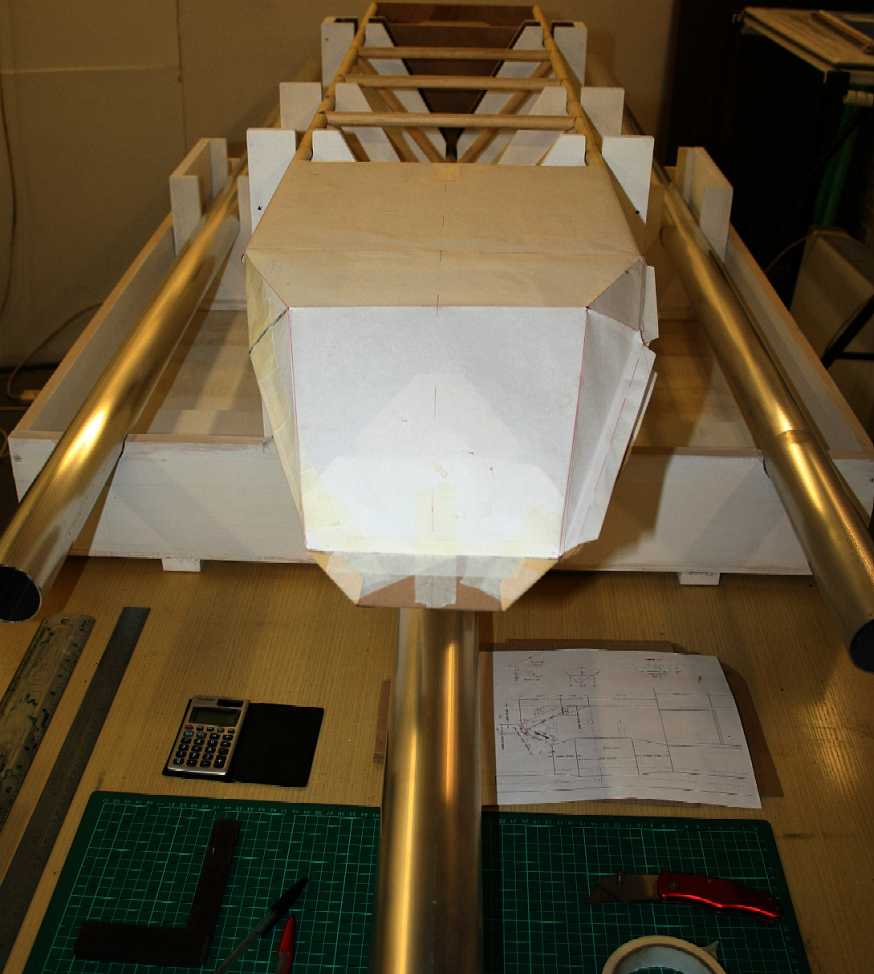

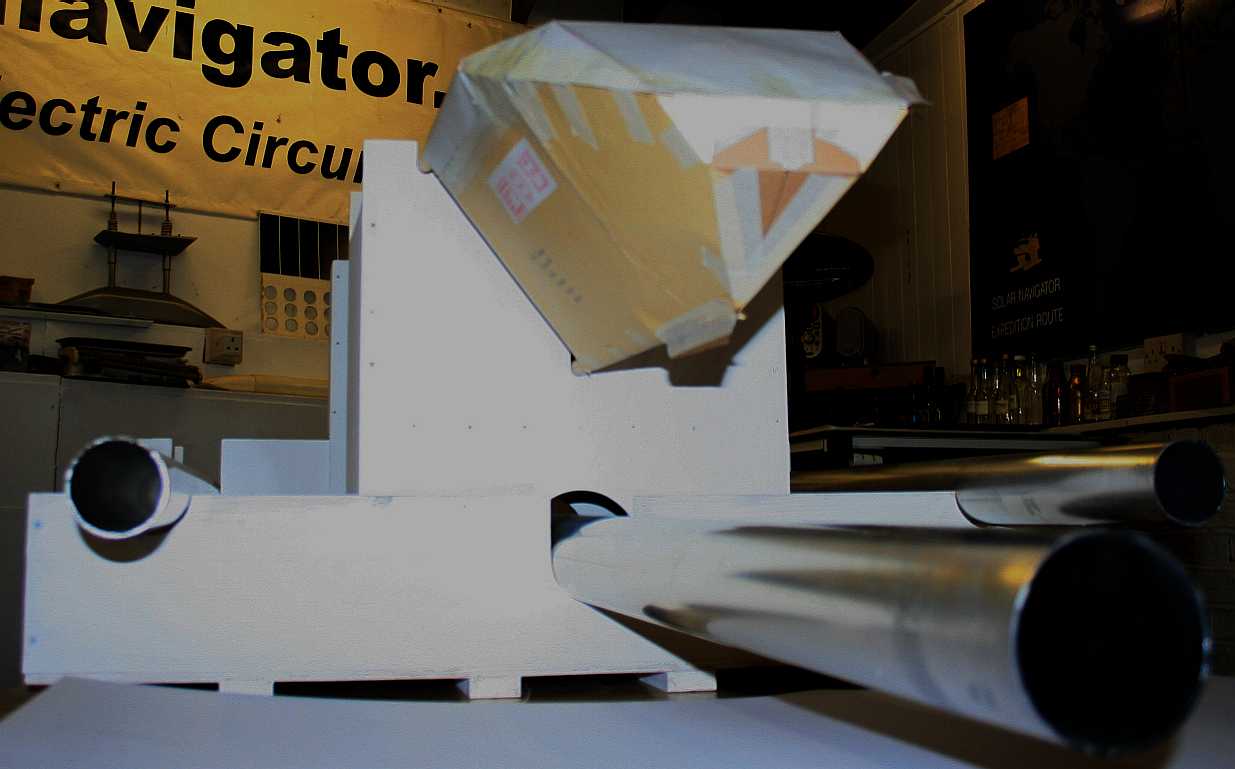

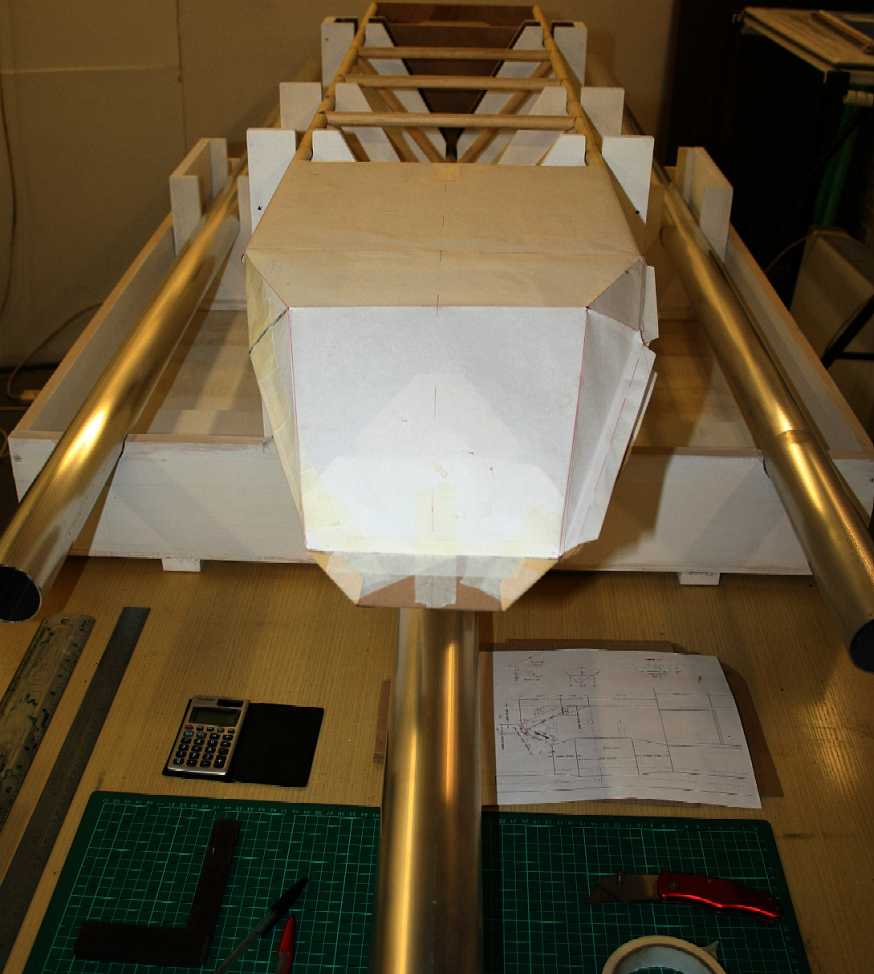

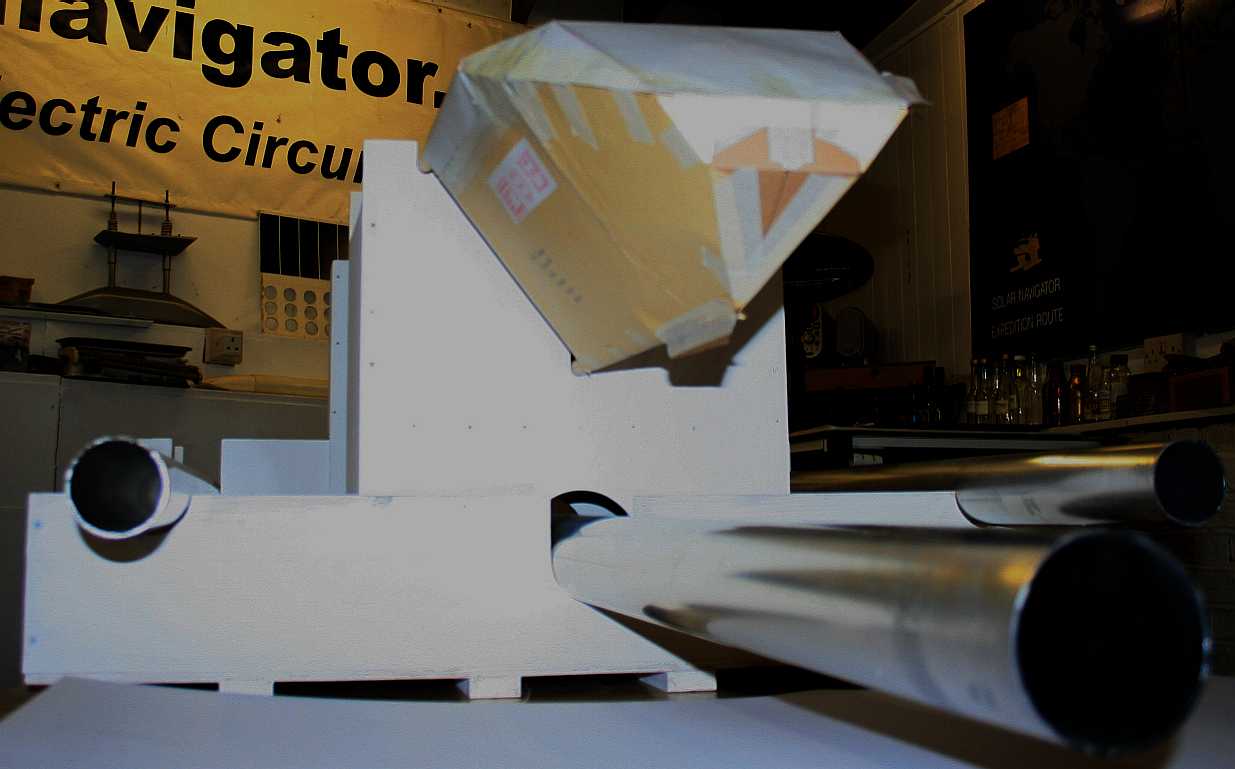

She

is starting to look like the 1/200th model. We hope the envelope includes a

return address in case the open water trials go haywire. Many of the

Microtransat teams will (we hope) see the funny side of this. We are identifying

minor practical improvements to the jig as we go. It is very rewarding watching

an idea come to life from the drawing board - and we still use a conventional A1

drawing board. We also have an A0 size unit that stays tucked away because it is

too big for our modest workshops.

The

development would have been better using a thick cartridge paper, or heavy duty

lining paper. We didn't have the time to go shopping or wait for online

deliveries. So we used what was lying about in the office, including recycling

old envelopes and cardboard boxes. This picture shows the tucks for the port

side window frames. These are important for joining and must overlap internally

with sufficient width for either riveting or welding. A common mistake is not

including a return - which can make production difficult. A suitable return also

reinforces joins, apart from making the assembly process more idiot proof - and

we need plenty of that.

Sorry

about the poor quality of this picture, but it shows the starboard side window

tucked and folded nicely with returns that are deep enough to make pop riveting

an option. Masking tape that is not too sticky, is ideal for when the unfolding

process begins. Have a sharp Stanley knife to hand, just in case.

From

the folding of the paper development, fine adjustments to the cuts are noted and

incorporated for future reference. It's a bit like assembling a kitchen

flatpack. The first one takes more time as you figure out the assembly sequence.

For example, the folds on the window frames worked better at a slightly

different angle to that envisaged in the design drawings.

|

LEG

|

NAUTICAL

MILES

|

TIME

IN PORT

|

WAYPOINT

|

SUNSHINE

DAYS

|

|

-

|

-

|

-

|

-

|

-

|

|

|

-

|

-

|

Monaco

|

0.00

|

|

1

|

784

|

2

|

Gibraltar

|

4.67

|

|

2

|

729

|

2

|

Tenerife,

Canary Islands

|

4.34

|

|

3

|

3,154

|

2

|

Trinidad,

Port of Spain

|

18.77

|

|

4

|

1,182

|

2

|

Panama

City

|

7.04

|

|

5

|

970

|

2

|

Galapagos

|

5.77

|

|

6

|

3,640

|

2

|

Tahiti

|

21.67

|

|

7

|

1,423

|

2

|

Tonga,

Nukualofa

|

8.47

|

|

8

|

410

|

2

|

Fiji,

Suva

|

2.44

|

|

9

|

1,886

|

2

|

Port

Moresby PNG

|

11.23

|

|

10

|

340

|

2

|

Thursday

Island, Cape York

|

2.02

|

|

11

|

724

|

2

|

Darwin

|

4.31

|

|

12

|

1,572

|

2

|

Jakarta,

Indonesia

|

9.36

|

|

13

|

1,881

|

2

|

Colombo,

Sri Lanka

|

11.20

|

|

14

|

2,109

|

2

|

Aden,

Yemen

|

12.55

|

|

15

|

698

|

2

|

Jeddah,

Saudi Arabia

|

4.15

|

|

16

|

670

|

2

|

Port

Said, Egypt

|

3.99

|

|

17

|

1,111

|

2

|

Palermo,

Sicily

|

6.61

|

|

18

|

170

|

2

|

Naples,

Italy

|

1.01

|

|

19

|

393

|

|

Monaco

|

2.34

|

|

-

|

-

|

-

|

-

|

-

|

|

-

|

23,846

|

36

|

RUNTIME

DAYS @ 7kts

|

141.94

|

|

-

|

-

|

-

|

-

|

-

|

|

+

10% service

|

=

156.13 Days

|

-

|

7

KNOTS AVE INC PORT & %

|

192.13

|

|

-&

maintenance

|

-

|

-

|

AT

6 KNOTS AVE

|

224.16

|

|

-

|

-

|

-

|

AT

5 KNOTS AVE

|

268.99

|

TRANSIT

EXAMPLES - The above table illustrates one of the most likely

ocean awareness expedition routes that could be undertaken by the Elizabeth

Swan, showing the time elapsed in days for 7 knots average cruising

speed, including times for 5 and 6 knot averages - allowing for 10%

downtime and 36 days in ports. Hence, although the objective is to reduce

the current solar circumnavigation record from 584 days, the event in not

an outright non-stop yacht competition in the offshore racing sense. It

remains to be seen how accurate such a prediction might be.

The

distance between submerged hull and helm superstructure determines the performance

of the full size vessel in heavy seas. The next development is the fore and aft

foils. These are very important and must have just the right amount of reserve buoyancy

to keep the hulls running true. Too much buoyancy and the SWASH

hull qualities are lessened. That is of course a design compromise - better

tested at this scale when modifications are not that expensive. Yes, we've

learned the hard way.

A

design of this caliber deserves a suitably sculptured figure head. The Solar

Lady will adorn the full size vessel at somewhere between 2.5 and 5.0 meters.

The mermaid inspired carving shown here would be 5.1 meters on the full size

craft. Weight is a consideration. The Solar Lady sculpture is far to valuable to

include for model tank and open water testing .

To

make the foils we begin by shaping up some solid timber to make a wooden buck.

Over this former we can then bend aluminium sheet blanks to make as many foils

as we want, all to the same section. This is important where we are making

several versions of the same hull, a civilian survey vessel and a couple of

military concepts, to include a micro-battleship

and a mini aircraft

carrier that carries a squadron of drone quadcopters.

JOINING

ALUMINIUM We

will be using a combination of alloy welding/brazing - and pop riveting to make

these test models. The full size robot ship will be mostly MIG and TIG welded.

Fortunately, for the proposed Kickstarter project in 2015, one of our in-house

boat builders is a skilled welder.

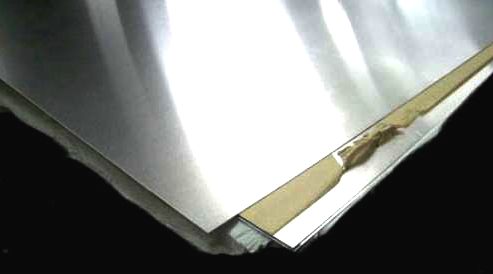

Aluminium

raw materials 6063T6 and 5251 H22 grades ordered June 21st 2013 from Aluminium

Warehouse, which company offers a friendly, efficient service within the United

Kingdom, and simply superb packaging as you can see for yourselves:

F.

COSTING ESTIMATES ALLY FOR R/C MODEL ACTIVE HULL BUILD @ 1/20TH SCALE

|

| 4 |

2000

mm x 1000 mm x 1.0 mm - 5251 H22 - Standard mill finish |

£18.60

|

£74.40

|

| 2 |

Aluminium

Round Tube (6063T6) 21/2 in x 16 swg -

2500 mm |

£

9.76

|

£19.52

|

| 1 |

Aluminium

Square Tube (6063T6) 3/4 in x 3/4

in x 16 swg - 2500 mm |

£

3.63

|

£

3.63

|

| 5 |

Aluminium

Round Tube (6063T6) 1/2 in x 18 swg - 2500

mm |

£

1.72

|

£

8.60

|

| 1 |

Aluminium

Round Tube (6082T6) 23/4 in x 16 swg -

5000 mm |

£22.72

|

£22.72

|

| 2 |

Aluminium

Round Tube (6063T6) 3 in x 16 swg - 2500 mm |

£12.49

|

£24.97

|

| 2 |

Aluminium

Round Tube (6063T6) 3/8 in x 16 swg - 2000

mm |

£

2.40

|

£

4.80

|

| 5 |

Aluminium

Round Tube (6063T6) 5/8 in x 18 swg - 2500

mm |

£

2.80

|

£14.00

|

|

| Sub-Total

(ex VAT): |

|

£172.65

|

| Price

Break Discount (ex VAT): |

|

-

£ 8.63

|

| Sheet

Metal Shipping Rate (ex VAT): |

|

£

49.90

|

| UK

VAT 20.0%: |

|

£

42.78

|

| Total: |

|

£256.70

|

K.

COSTING ESTIMATES

FOR R/C MODEL ACTIVE HULL BUILD @ 1/20TH SCALE

| . |

| Heating |

. |

300 |

| Power

& lights |

. |

200 |

| Labour:

fabrication |

.26

weeks |

13,000 |

| Tank

and open water testing |

.4

weeks |

2000 |

| Insurance |

. |

600 |

| . |

. |

. |

| Mothership

build |

Sub

Total |

£

15,500 |

| . |

. |

. |

| Contingency |

@

35% |

£

5,425 |

| . |

. |

. |

| . |

Build Total |

£ 20,925 |

BLUEFISH:

BLUEBIRD

MARINE SYSTEMS TEST PROJECT

TIMETABLE & KICKSTARTER 2014?

The

model(s) seen on these pages are being constructed under license for hydrodynamic

tank tests, self righting and open water sea-keeping in line with other models tested -

using radio

control initially, then switching to computer micro-controllers for

fully autonomous robotic

control and AI.

The

sensor/computer package to be used in this model as "proof of concept"

is to be revised to incorporate state of the art marine navionics for ocean

going vessels. The model will be COLREGs

compliant.

(1)

Build tank test models

(2)

Test and collate results in tank and open conditions

(3)

Make any necessary adjustments to design

(4)

Retest model in tank and open conditions

(5)

Incorporate results into final design

(6)

Begin autonomous fit-out

(7)

Autonomous systems check

(8)

Autonomous trials

(9)

Autopilot/GPS waypoint trials on pond

(10)

Full combined autonomous mission

WHY

USE ALUMINIUM ?

In

our opinion Aluminium is the best material for the construction of robust workboats. A relatively large craft built from aluminium will be lighter and stronger than if it where built from fibreglass. Marine grade aluminium has such high impact resistance, that a Buddy boat can withstand a collision that would seriously damage a fibreglass craft. Marine grade aluminium also has excellent corrosion resistance, in most cases aluminium boats will last up to 50 years in the harsh saltwater environment. Aluminium is by far the lowest maintenance material that could be used for boat manufacturing. Aluminium does not rust or rot. Residual values for aluminium boats are high - making overall cost of ownership low.

STRENGTH

OF ALUMINIUM

Aluminium has a higher yield strength than steel. It takes a force of around 30,000 psi (207MPa) to bend mild steel to the point where it won't spring back into shape when released. This is known as the 'yield strength'.

5-series Aluminium alloys will not yield until about 39,000psi (275MPa) - roughly 30% stronger than steel. A typical

fibreglass hull, by comparison, is fairly brittle and will crack before flexing significantly.

In practice this means that an aluminium boat will be able to withstand collisions that would dent the same boat made of

steel, and write off the same boat made of

GRP.

|

Material

|

Aluminium

|

Steel

|

|

Weight

|

2.65t/m3

|

7.86t/m3

|

|

Yield

Strength

|

275MPa

|

207MPa

|

|

Ultimate

Tensile Strength

|

310MPa

|

345MPa

|

|

Corrosion

resistance

|

Excellent

|

Poor

|

|

WEIGHT OF

ALUMINIUM

Aluminium is only around 35% of the weight of steel. This means that given a weight constraint, we can afford to use about 3 times more material in an aluminium boat than in steel - allowing us to use thicker shell plating, bulkheads, frames and decking.

A lighter vessel is easier to launch/recover by road trailer and typically only requires half the engine horsepower to match the performance of a similarly sized

GRP boat. That said, carbon

fibre is a much stronger material.

DURABILITY

OF ALUMINIUM

5083

and 5383 marine-grade aluminium alloys are preferred for marine applications because of its strength and resistance to salt-water. It has the highest strength of the non-heat treatable aluminium alloys and retains exceptional strength after welding. Marine-grade 5083 has a working life of around 100 years.

Aluminium corrodes differently to steel. Unprotected steel will rust when it comes into contact with

oxygen and water and the resulting layer of corrosion is still permeable, meaning the material can rust right through if unchecked and untreated.

When aluminium corrodes the resulting layer of oxidation is air-tight and rock hard, keeping the material underneath

highly protected. Even scrapes and scratches will form their own protective coat over time. This is why

most alloy boats are not painted, and the majority of operators choose not to

anti-foul - further reducing maintenance costs and environmental

impact.

SEAVAX

- The making of a small proof of concept workboat in aluminium sheet.

COST

OF ALUMINIUM

The initial outlay for an aluminium craft may be higher than that for a comparable steel or fibreglass build,

but that cost will quickly be recouped:

>

Hull maintenance typically amounts to a cursory visual inspection, regular cleaning and replacement of the sacrificial anodes. This should keep the hull looking like new in 10 years time.

>

Aluminium does not need any protective painting, and the majority of operators do not apply anti-foul - this saves the cost of regular rubbing down and re-painting. The money you will have saved having your steel boat repainted will more than pay back the difference.

>

Being lighter, aluminium vessels can operate with smaller engines than similar steel and fireglass builds, offering a saving on the initial cost of an engine and superior fuel

economy - a real bonus with a solar powered ship.

>

Aluminium vessels have a high resale value thanks to the long life and high durability of the material.

At the end of a vessel's working life, the aluminium can be sold for

recycling, also reducing the impact of natural resources.

ADAPTABILITY

Aluminium vessels lend themselves to customization like steel. Unlike fibreglass (which would require a mould for every permutation of the design), we can start with a basic hull and easily change the length, beam, cabin layout, deck configuration, etc. to suit

the intended use. We use a CAD system that allows us to quickly modify hull

designs to suit a particular needs and keep costs down.

|

ALUMINUM

ALLOYS

|

1100

- This low-strength alloy has excellent

corrosion-resistance, has satisfactory anodizing and

conversion coating finishing characteristics, and is

unmatched by any other commercial aluminum alloy in

workability. It lends itself readily to welding, brazing

and soldering, but tends toward gumminess when machined.

Typical end uses are spun holloware, fin stock, chemical

storage, and processing equipment, kitchen utensil items,

and general sheet metal work.

3003

- About 20% higher in strength than 1100 but retaining an

excellent workability rating. May show some slight

discoloration when anodized, but reacts well to mechanical

and organic finishings. Is easily welded and brazed, but

soldering is limited to the torch method. Like 1100, tends

to be gummy when machined, but will perform somewhat

satisfactorily in the higher tempers withthe proper set-up

and maximum speeds. Typical end uses include food and

chemical handling equipment, appliance components,

truck/trailer roofing, heat exchangers, pipe jacketing and

lawn furniture components.

5005

- Comparible to 3003 in strength and close to it in

formability, but this alloy has superior finishing

characteristics making it much better for anodizing.

Excellent corrosion-resistance and weldability, but would

rate somewhat below 1100 and 3003 for brazing and

soldering, and it is not the alloy one would choose for

machinability. Typical end uses are decorative trim,

utensils, mobile home siding and reflectors.

5052

- For many years, until the advent of 5083 and 5086, this

alloy was the highest strength non-heat-treatable alloy

commercially available. Although easily welded, it is not

recommended for brazing and soldering applications.

Excellent corrosion-resistance, particularly in marine

applications, and adapts to most mechanical and finishing

processes although the heavier anodic fi lms may take on a

yellowish cast. Fair machining with proper set-up. Typical

end uses include fuel tanks, truck-trailer side panels,

small boat hulls, truck cabs, bumpers, storage tanks and

pressure vessels.

5083

- With excellent corrosion-resistance and weldability,

together with high strength, this alloy was designed for

welded structures requiring maximum joint strength and

efficiency. Can be anodized for increased

corrosion-resistance, but does not lend itself to

decorative applications. Not meant to be a machining

alloy, but can be machined fairly well with proper

preperations. because of its relatively high magnesium

content, the workability rating would be only fair.

Typical end uses are large marine craft, containers,

railroad cars, structurals and elevator cars.

|

5086

- Has excellent corrosion-resistance and weldability. Can

be anodized for increased corrosion-resistance, but does

not lend itself to decorative applications. Not meant to

be a machining alloy, but can be machined fairly well with

proper applications. Because of its relatively high

magnesium content, the workability rating would be only

fair. Typical end uses are marine craft, containers,

railroad cars, structurals and elevator cars.

5383

- 5383 alloy offers a 15% higher welded strength than

standard 5083 and may be used wherever a stronger welded

aluminum structure is desired, from hulls to

superstructures. Marine structures benefit from the

excellent corrosion-resistance offered by 5383. Smaller

boats (< 168 ft) benefit from improved scantlings,

which translate into structural weight savings on patrol

craft, increased strength on work boats and added interior

space in luxury yachts. Larger vessels (> 168ft )

profit from the increased strength and improved fatigue

behavior of 5383 alloy. Cruise ship superstructures can be

lightened further while improving stability and not

compromising strength or corrosion-resistance.

5456

- Highest in strength of the commercially available

non-heat-treatable alloys with excellent

corrosion-resistance. Only fair workability and

machinability, but excellent weldability. Not recommended

for brazing or soldering. Typical end uses are

high-strength welded structures, marine components,

pressure vessels and storage tanks.

6061

- Very good corrosion-resistance and finishability plus

excellent weldability and a strength level approximating

that of mild steel, this is a popular general-purpose

alloy. Machinability is good and, in the annealed state,

its workability carries a high rating, staying at the

"good" level if heat-treated without aging.

Typical end uses are aircraft landing mats, large and

small marine vessels, structural architectural parts,

storage tanks and highway signs.

6063

- A heat-treatable alloy developed exclusively for the

extrusion industry and the most important alloy in the

magnesium silicide group. Its as-extruded finish is quite

good making it satisfactory for many applications without

any additional work. Lends itself to comparatively

intricate sections making it the leading architectural

extrusion alloy. Also finds use in some decorative

applications, furniture tubing and ladder parts.

|

ALUMINUM

TEMPERS

"H"

temper-non-heat-treatable alloys / strain-hardened

|

H14

- Strain hardened (cold worked) without thermal treatment

and 1/2 hard.

H22

- Strain hardened and partially annealed, 1/4 hard.

H32

- Strain hardened and stabilized by low temperature

heating, 1/4 hard.

H34

- Strain hardened and stabilized by low temperature

heating, 1/2 hard.

|

H111

- Applies to products which are strain-hardened less than

the amount required for a controlled H11 temper.

H112

- Applies to products which acquire some temper from

shaping processes not having special control over the

amount of strain-hardening or thermal treatment, but for

which there are mechanical property limits

H116

- Applies to products manufactured from alloys in the 5xxx

series, for which the magnesium content is 3% nominal or

more. Products are normally strain hardened at the last

operation to specified stable tensile property limits and

meet specified levels of corrosion-resistance in

accelerated type corrosion tests. They are suitable for

continuous service at temperatures no greater than 150°F

(66°C). Corrosion tests include inter-granular and

exfoliation.

|

"T"

temper-heat-treatable-alloys / thermally treated

|

T6

- Solution heat-treated and artificially aged. A stable

temper.

T52

- Stress-relieved by compressing. Applies to products

which are stress-relieved by compressing after solution

heat-treatment, to produce a permanent set of 1 to 5

percent.

|

T651

- Solution heat treated, stress-relieved by stretching and

artificially aged. Equivalent to T6 and applies to plate

and rolled bar except 2219

T6511

- Solution heat treated, stress-relieved by stretching and

artificially aged with minor straightening. Equivalent to

T6 and applies to extruded rod, bar and shapes except

2024.

|

|

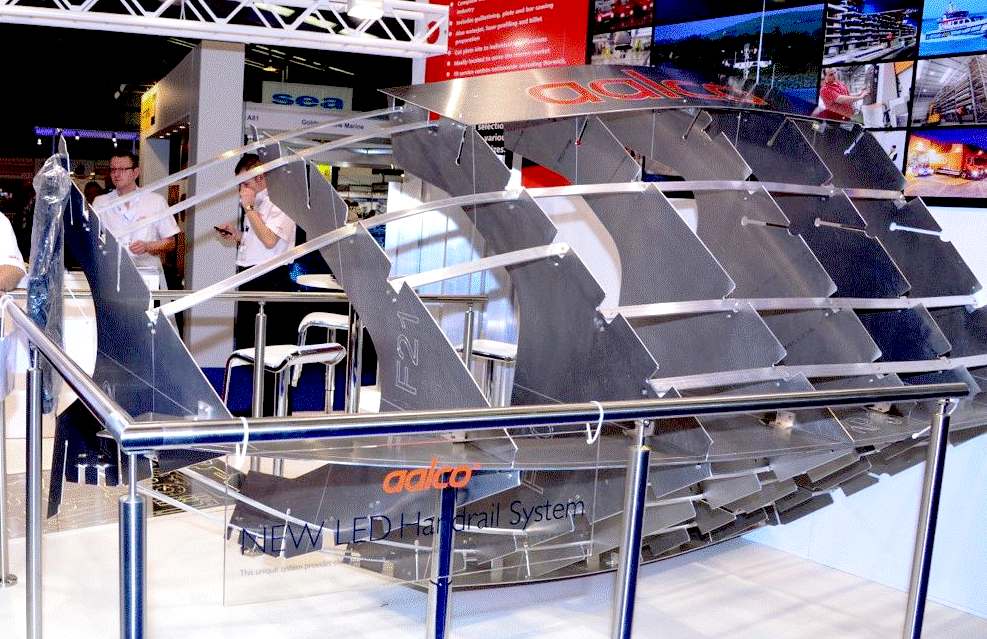

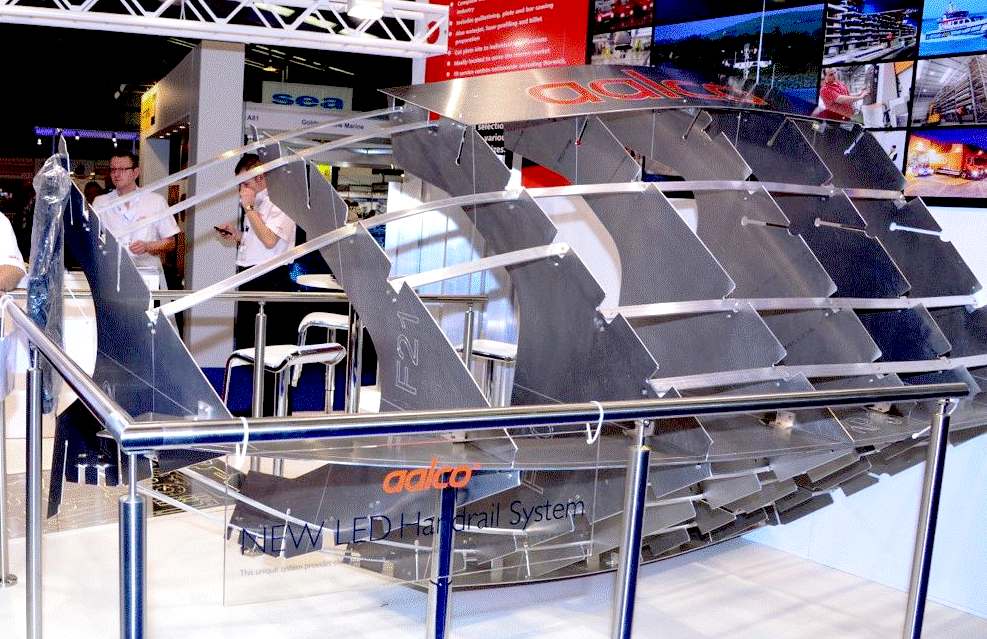

SEAWORK

2013 - At a time when some trade exhibitions seem to struggling, the busy gangways and strong visitor numbers to the stands at Seawork mark a pleasant departure from what has, all too often, become the norm at other events, according to

Aalco.

“Aalco Metals had a very positive experience at Seawork 2013,” reports Sales Development Director, Clive Bush. “The organisers have got it right; they put on the exhibition and do a first class job delivering the right audience. Of course, it is the exhibitors’ job to provide interesting and eye-catching displays, but past experience has shown that our investment in this particular event pays dividends.

“In addition to key UK customers, we noted a significant number of visitors from overseas which is very encouraging”

Seawork 2013 marked the fifth successive year that Aalco Metals has taken part and the company has already re-booked for next year.

More information at www.aalco.co.uk

30

JAN 2015 - A German company has developed a new approach to building workboats. Instead of doing the whole of the construction in a boat yard,

Ophardt Maritim builds a range of hulls in aluminium and supplies these to owners or other shipyards for completion and fitting out.

The Opship hulls are supplied as the basic open hull, what the company calls a Boat Chassis, which gives the recipients a proven design on which to develop their own ideas for the completed vessel.

The aluminium hulls are designed in three sizes and they are all based on a unique hull design that features a moderate vee hull with wide chines for easy planing. There is a deep narrow forefoot to improve the low speed handling and a flare in the bow to provide a dry ride.

The hulls are primarily designed to accommodate outboard power with up to triple 300 hp outboards on the largest of the hulls to give high speeds. To fit these power units a bolt-on module is attached to the transom. Fuel tanks can be specified if required. Alternatively the hulls can be specified for electric propulsion using the range of Deep Blue 80 electric outboards produced by Torqeedo and with a battery pack to offer range of over 50 miles at low speeds but with the larger electric outboards, a speed of 12 knots can be achieved but with a more limited range.

The aluminium hulls are fully welded using 8 mm plating and fitted with closely spaced transverse framing. This framing is both welded and glued in place, the glue creating a form of insulation that is designed to reduce the sound. An interior deck can be supplied over the frames or these can be left exposed for the final builder to complete as required.

The concept of the hulls developed by Ophardt Maritim is to offer an advanced and tried and tested hull concept at an attractive price. These hulls are designed to meet the demands for a wide variety of workboat roles from fast patrol boats to rugged harbour workboats. They are currently produced in sizes from 8 metres up to 12 metres and one of the main advantages is the quick delivery time. Also by focussing on just producing hulls in aluminium Ophart is able to invest in advanced construction techniques.

CONTACTS

- Ophardt R + D GmbH + Co. KG • Hafenstraße 69 • D-47119 Duisburg. Telefon: +49 203 - 500 322 0.

Fax: +49 203 - 500 322 51. E-Mail: info@ophardt-maritim.de

BLUEFISH

DEVELOPMENT PROJECT INDEX A-Z

GENERAL

LINKS

Maritime

Journal a new approach to aluminium workboat building

Ophardt-Maritim

http://www.ophardt-maritim.de/startseite/

http://www.maritimejournal.com/news101/vessel-build-and-maintenance/ship-and-boatbuilding/a-new-approach-to-workboat-building

Bluebird

Marine Systems Ltd

Solar

House, BN27 1RF, United Kingdom

+

44 (0) 1323 831727 +44

(0) 7842 607865

INTERESTING

EARLY

DEVELOPMENT TEST MODELS - LINKS

Blackcurrant

1 | Blackcurrant

2 | Catamaran

Hull Design

Drag

| SWASH |

SWATH

| Trimaran

|