|

WIND & WATER - TANK / TUNNEL TESTING

|

||

|

BRICKWORK - CARRIAGE - DRAINAGE - FACILITIES - FILTRATION - GLASS & PAINT - GANTRY - GIMBALS - HATCHES HYDRODYNAMICS HISTORY - INSTRUMENTS - LABORATORY - LAMINATING - LOGISTICS - OUR TEST TANK - PROOFING - REVIEWS - SCREED SEAVAX TEST VIDEOS - SLUICE GATE - SOLAR BATTERIES - WAVE MAKING - WIND MACHINE

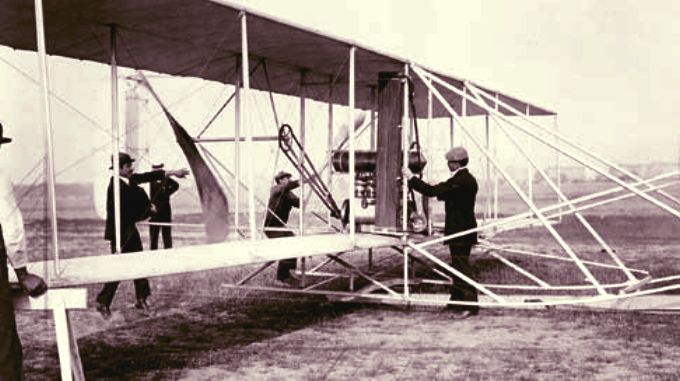

In the old days thought was given to streamlining the shape of airplanes, boat hulls and car bodies. But there was not much scientific measurement. If a new shape went faster than an earlier shape, that was good enough. The principle of drag and teardrop shapes to reduce drag was well enough understood. But then thought of testing a shape before building a vehicle, to predict performance, was made a reality by the Wright Brothers in 1903, though nobody would pay them for a patent license in the USA and Europe aided such refusal in refusing to issue a patent to them at all.

WIND TUNNELS

A wind tunnel is a tool used in aerodynamic research to study the effects of air moving past solid objects. A wind tunnel consists of a closed tubular passage with the object under test mounted in the middle. A powerful fan system moves air past the object; the fan must have straightening vanes to smooth the airflow. The test object is instrumented with a sensitive balance to measure the forces generated by airflow; or, the airflow may have smoke or other substances injected to make the flow lines around the object visible. Full-scale aircraft or vehicles are sometimes tested in large wind tunnels, but these facilities are expensive to operate and some of their functions have been taken over by computer modeling - hence our consideration of small scale test facilities.

Wind tunnels were first proposed as a means of studying airplanes in free flight. The wind tunnel was envisioned as a means of reversing the usual paradigm: instead of the air's standing still and the aircraft moving at speed through it, the same effect would be obtained if the aircraft stood still and the air moved at speed past it. In that way a stationary observer could study the aircraft in action, and could measure the aerodynamic forces being imposed on the aircraft.

Wind-tunnel testing was applied to automobiles, to determine ways to reduce the power required to move the vehicle on roadways at a given speed. In these studies, the interaction between the road and the vehicle plays a significant role, and this interaction must be taken into consideration when interpreting the test results. In an actual situation the roadway is moving relative to the vehicle but the air is stationary relative to the roadway, but in the wind tunnel the air is moving relative to the roadway, while the roadway is stationary relative to the test vehicle.

One of the biggest tow tanks in the world, top, left. Top right: The Jere A Chase Ocean Engineering Laboratory at the University of New Hampshire, and bottom, centre, the tow tank of the Australia Maritime College in Tasmania

WATER TOW TANKS or SHIP BASINS

A ship model basin is a physical basin or tank used to carry out hydrodynamic tests with ship models, for the purpose of designing

and refining a ship's performance at sea.

As you might imagine the cost of building and maintaining such installations is substantial.

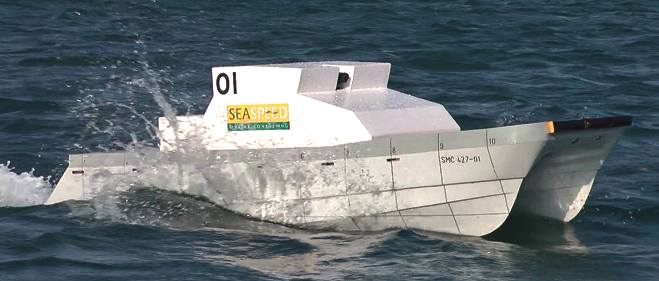

The 'Mosquito' trimaran by 'M Ship' is a floating test rig that measures the forces on model hulls mounted on booms ahead of the craft - port and starboard. One slight snag is that the operator has no control over the weather. So, if it's stormy for a few days, the convenience is quickly lost. That said, it is a low cost solution that could become very popular, and a welcome innovation.

M SHIP REI (FLOWT)

Enter one possible solution: According to M-Ship, the Rapid Empirical Innovation design & development services program takes the tank out of "tank testing" when it comes to traditional hull evaluation. As you can see from the picture above, REI does what it says on the can.

The U.S. Patent and Trademark Office has granted MSHIPCO a patent for its Rapid Empirical Innovation (REI®) process including model testing method, platform structure and data acquisition systems. “Time and money are two of the biggest barriers to naval innovation,” Bill Burns, Co-Founder of MSHIPCO is quoted as saying. “The REI® platform lowers the cost of discovery by giving naval architects a practical, low-cost tool to explore ship design concepts in real time and real world.

The low cost of using the system might mean that valuable design concepts that otherwise would lie dormant and unexplored - actually get a look in. Hull models are evaluated on a platform that provides real-time force, trim and acceleration measurements to optimize performance and ride quality.

OUR TEST TANK

We are building our own water test tank to be able to conduct discreet development that might otherwise spoil patent protection from accidental disclosure.

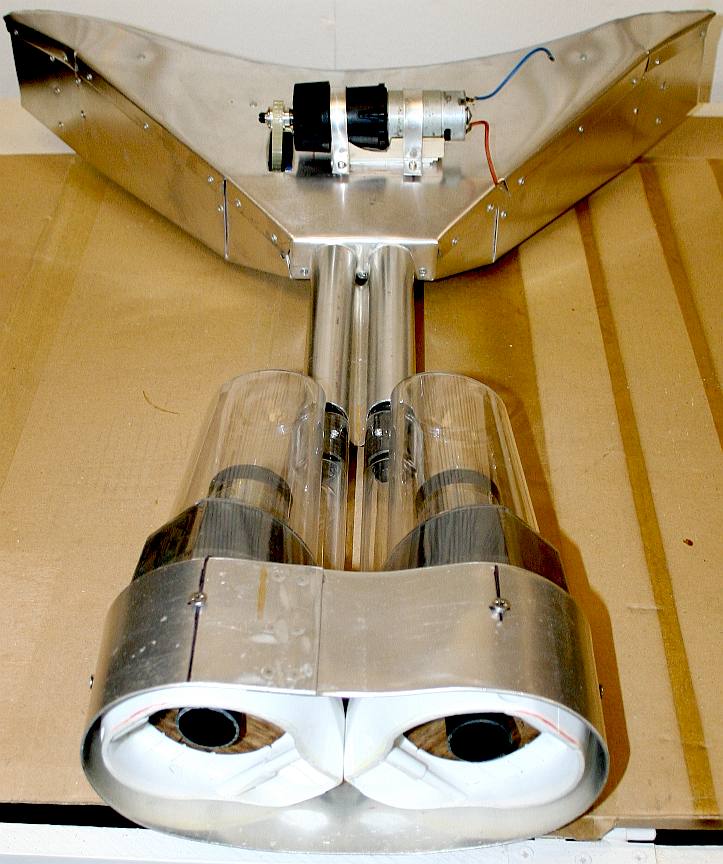

SEAVAX RECIRCULATING TEST TANK - Twin pumps and a vane guide system are inserted into the water tank for hydrodynamic hull evaluations. This makes a closed loop water-tunnel that offers a lot of options for considerably less money at the expense of lesser accuracy that needs to be compensated for. The picture below shows the test model @ 90 degrees to that seen above - for wind and wave tests. Wind tests are important for this vessel, where two wind turbines help to provide motive power from nature and so will tend to heel the boat in proportion to wind vector as with a sailing ship.

SEAVAX TEST TANK SIDE VIEW - This is a side view is of the overhead beams and stainless steel gantry. You can see the sluice gate in red on the left as a reference point. The gantry is of stainless steel "T" beam construction with four wheel bogies that supports a cross-beam, also of "T" section stainless steel. The model can be swiveled 360 degrees to point in any direction in the tank.

PATENT ABSTRACT US 8375782 B1 - Model hull testing method, platform, and system

A model hull testing method, platform, and system are disclosed that acquire model hull performance data about one or more hulls in an open-water environment, preferably testing two hulls simultaneously as they encounter essentially the same sea state. Avoiding tow-tank testing by providing a powered watercraft as an open-water testing platform, the method proceeds by supporting the model hulls on the testing platform, so they float in outboard positions, and then by acquiring data about hull performance as the testing platform and model hulls move together through an open body of water. A complement of data acquisition components acquires digital and analog data about the testing environment and model hull performance, preferably including platform motion, time and location information, wave characteristics, apparent wind speed and direction, and model hull drag and motion, with all data being recorded on an onboard laptop computer for later processing and analysis. A trimaran powered watercraft configuration and preferred data-acquisition components and techniques are also disclosed.

Never mind all the expensive testing equipment, just launch your model hull in the water and watch.

Superb photograph of an air lubricated hull undergoing tank testing.

OPEN WATER TESTING

One way of cutting costs to the bone is to use water in its natural state in ponds and lakes. As with the REI system, you are bound by the weather, but there is little cost, other than a movie camera and the operators time.

MARITIME JOURNAL 30 OCT 2014

The UK Ship

Simulation Centre houses the latest evolution of HR Wallingford’s advanced

navigation simulation technology: four real-time ship simulators, including two dedicated tug simulators. Each simulator is a functioning ship or tug’s bridge surrounded by a 360-degree simulated environment. The four simulators can be run separately or together to allow different vessels in the same simulated environment to interact. They can also link with the six simulators located in HR Wallingford’s Fremantle Ship Simulation Centre in Australia.

HR Wallingford web: http://www.hrwallingford.com/

An unusual water tank for testing ROVs from www.tyneandwearmarine.com

COMBINATION WATER/WIND TANK/TUNNEL

A combination wind and water tank/tunnel? There is no such thing at the present time and that is the whole purpose of this discourse. Why not? We are proposing doing away with the large tow tank basin and replacing it with a closed loop watercourse, powered by a pump.

The world's smallest scale (full featured) closed-loop wind tunnel is that developed for the Borzoi and Bluebird electric vehicles between 1987 and 1996, as seen on the www.speedace.info website (link below).

A desktop sized closed loop 5 element balance (to include lift and downforce measured via strain gauge bridges and amplifiers) upright wind tunnel. Featuring rotating object table, triple insulated floating fan unit, variable wind velocity, boundary layer injection/vacuum, smoke trailing, temperature gauges and hours run meter.

We can see no reason why a similar size unit cannot be laid on its side; the lower half filled with water, and the upper air. Instead of one large air fan unit, the water section has one or two pumps (jetski style impellors) that circulate the water via control fins, and the upper half has one or two fans that circulate the air - also via control surfaces. The air and water can be synchronized to run at the same speed or at variables, to include full reverse - and that's something no water tank or open water test rig can do. How about a patent Mr Comptroller? Oops, we've just published. Guess not then.

Instead of running a hull in water suspended from a rig running along a track, the hull is suspended in the water on an inverted (gimbaled) balance - and the water moves. You would then have a desktop tank test system. Such a system will be nowhere near as accurate as the multi million $dollar installations at our learned institutions, but, you would have at your fingertips a means to evaluate hull against hull rather more quickly and cost-effectively than with any other system - and get some ballpark figures, before committing to a large model. Simples.

Water is incompressible and that fact coupled with the low air speeds involved, makes the design of a combination water and air boundary tank a relatively easy task.

The 'Emerald' bulk carrier model hull undergoing tow tank tests.

CONTACTS

M Ship Co., LLC

BLUEFISH DEVELOPMENT PROJECT INDEX A-Z

HORIZON 2020 BID (withdrawn 2014)

HYDRO CYCLONES - This is the working head of a boat the vacuums plastic waste from the sea. Much hydrodynamic testing and development will be needed to make such a system efficient.

LINKS & REFERENCE

Maritime Journal 2014 Oxfordshire fast flow facility water test tank Seaspeed Trials and Testing south-boats AMC Model-test-basin-towing-tank http://www.hrwallingford-group.co.uk/ http://www.hrwallingford.com/ http://www.maritimejournal.com/news101/marine-civils/marine-civils/fast-flow-facility http://www.seaspeed.co.uk/Trials-and-Testing-Projects/south-boats https://www.amc.edu.au/ https://www.amc.edu.au/model-test-basin-towing-tank http://www.mshipco.com/rei.html http://www.cyberiad.net/leo.htm

BRICKWORK - CARRIAGE - DRAINAGE - FACILITIES - FILTRATION - GLASS & PAINT - GANTRY - GIMBALS - HATCHES HYDRODYNAMICS HISTORY - INSTRUMENTS - LABORATORY - LAMINATING - LOGISTICS - OUR TEST TANK - PROOFING - REVIEWS - SCREED SEAVAX TEST VIDEOS - SLUICE GATE - SOLAR BATTERIES - WAVE MAKING - WIND MACHINE

EARLY DEVELOPMENT TEST MODELS - LINKS

Blackcurrant 1 | Blackcurrant 2 | Catamaran | SWASSH | SWATH | Trimaran

|

||

|

This page is Copyright © 2018 Bluebird Marine Systems Ltd. The names AmphiMax™, Bluebird™, Bluefish™, Miss Ocean™, SeaVax™, and the blue bird & fish in flight logos are trademarks. All other trademarks are hereby acknowledged.

|

||