|

SEAVAX™ - HYDRO-CYCLONIC PLASTIC FILTRATION SYSTEM

|

||||

|

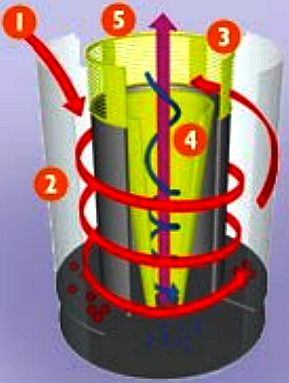

"DUAL-HYDROCYCLONE" STEP-BY-STEP

1. Dirty

water (plastic soup) is drawn in by a pump via a self-cleaning (automatic)

pre-filter that removes lighter particles. 2. This

water goes into the top corner of a drum or bin. The angle it enters the bin causes it to spiral around, creating centrifugal force. This force causes the larger

plastic particles to spin out of the water stream to be directed to a

collector and so separated from the carrier water. 3. The

water then flows through a filter, which catches more plastic particles. 4. The

water continues through a conical cylinder housed in the bin. The angle the

water enters from and the sloping walls of the cylinder combine to cause the

water, containing the smallest (dense) plastic particles, to spin down to the bottom of the cone at an increasing speed. 5. Centrifugal force acting on the water stream increases, forcing the plastic particles against the sides of the cone and through the hole in the bottom of the cone, while the water escapes up the centre. Simples.

Cyclonic,

or rather hydro-cyclonic separation is not stand alone as a system to

clean ocean waste, but coupled with other methods, a workable system is

possible. It's a bit like the combine

harvester. Before this machine revolutionized farming, it took three separate operations, comprising:

harvesting - reaping, threshing, and winnowing - into a single process.

MULTI-STAGE HARVESTING HEAD

Just like the combine harvester, there will need to be several stages and methods of collecting and sorting the different types of ocean (mostly plastic) waste.

There is surface floating waste, such as from rivers, bottles, fishing nets and other large plastic products that will need to be scooped from the ocean safely, then shredded.

Then there are the smaller particles that make up roughly 80% of the plastic in the 5, or is that really 7 gyres, including the one forming in the Arctic Ocean. We treat the North Pacific as two separate gyres. Others class that as one. The smaller plastic bits float below the surface at various depths.

Shredding is not necessary for the small plastic pieces, but we do not want to scoop up plankton or other small life-forms - just the plastic - entailing smart fishing. The majority of plastic fragments are less than 1 cm in size – no bigger than your little fingernail – with a mass less than 0.15 g. This size particle will require a dedicated hydro-cyclonic chamber, or chambers. It may be possible to vacuum up the plankton and pass it through the system unharmed, while taking out the toxic plastic.

We don't want shredded waste passing through these hydro-cyclonic chambers. Smaller particles will need additional treatment. A similar technique is employed in the modern "dual-cyclone" vacuum cleaners made famous by Sir James Dyson.

A hydro-cyclone will normally have a cylindrical section at the top where liquid is being fed tangentially, and a conical base. The angle, and hence length of the conical section, plays a role in determining operating characteristics. For industrial applications it is usual to employ a battery of separators to increase volume handling. Also, filtration can be staged to cope with different particle sizes. The example seen above is not ideal for SeaVax, being a radial arrangement, where in the SeaVax, a battery of separation heads joined to a manifold in linear fashion, may be more suitable for a three stage treatment system. A key difference between hydrocyclones and centrifuges is cost. Centrifuges are expensive precision rotating machines that often need sophisticated control, whereas hydrocyclones have no moving parts and few controls are needed, so they are lower cost (solid-state) devices.

GRADING & HYDRO-CYCLONIC SEPARATION

The ocean is acting as a giant filter. It could then be argued that this is the first stage of filtration - actually concentration - a plastic stew just begging to be harvested. Once the seawater plastic waste (plastic soup) is caught, the plastic, which can contain fishing nets and other difficult to handle materials, needs to be graded. This is done by chopping the garbage mix into convenient sized pieces with a suitable shredder, ready to be fed into a bank of separation units. Most of the plastic is in small bits, so that is a priority. At the moment we are working on three stages to grading of incoming waste, the final stage being the transportation of solids (and/or liquids) to a holding bay, or tank as the case may be for transfer to ZEV barges.

Hydrocyclones can be made of metal (mostly steel), ceramic or plastic (such as polyurethane, polypropylene, or other types). Metal or ceramic hydrocyclones are used for situations requiring more strength, or durability in terms of heat or pressure. When there is an occurrence of much abrasion (such as occurs with sand particles) polyurethane performs better than metals or ceramics. Metal lined with polyurethane is used in cases of combined abrasion and high pressure. We need a system that is long-lived and easy to service when in dock. This is after all an industrial application, where cost of cleanup is a major factor.

In a suspension of particles with the same density, a relatively sharp cut can be made. The size at which the particles separate is a function of cyclone diameter, exit dimensions, feed pressure and the relative characteristics of the particles and the liquid. Efficiency of separation is a function of the solids' concentration: the higher the concentration, the lower the efficiency of separation. There is also a significant difference in suspension density between the base exit (fines) and the apex exit, where there is little liquid flow.

If the size range of the particles is limited, but there are differences in density between types of particles, the denser particles will exit preferentially at the apex. The device is therefore a means of selective concentration of, in this case, plastics. This technology is particularly useful for extracting fine plastic particles.

A hydrocyclone is related to the centrifuge; both of them are intended to separate heavies and lights in liquid by the application of centrifugal force. That of course takes a lot of energy - and that is why we need solar and wind power, simply to have sufficient energy at our disposal to do useful work. A SeaVax ZCC (Zero Carbon Cruiser) is likely to travel a lot slower than its conventional, Bluefish ZCC, propeller driven counterpart. But speed is relative. In this case speed of harvesting the plastic is the main criteria.

Generally, hydrocyclones are used in continuous flow systems so that the instantaneous liquid inflow to the hydrocyclone is equal to the total instantaneous outflow of "lights" plus "heavies".

Two more examples of hydrocyclonic heads. The one on the left is a bolt together model. The one on the right uses just seven fasteners for a complete rebuild. A twist-to-lock option simplifies apex removal and service, and drop-in glue-free liners reduce build time. Tongue and groove mating surfaces foster precision alignment. Long-lasting urethane and ceramic cones and powder-coated steel construction resist corrosion and damage. By adding weep holes for early wear detection, customers can virtually eliminate unplanned outages. These units are available in eight sizes ranging from 2.5 inches to 33 inches. We would add sensors to monitor performance autonomously.

PUMPS & PUMPING

Where the SeaVAx (like any vacuum cleaner) is basically a huge pump, typically screens would be used to stop trash and debris from entering a pump and causing costly breakdowns. Here, we want the trash to enter our pump, but in such a way that we can handle it, which includes filtration to take out any damaging waste. There will be automatic shutdown in cases where marine life is detected, coupled with an SOS beacon to alert rescue workers to a potential life endangering situation. Too many marine animals are being caught up and drowned by nets and the like.

Quite often the solution to a problem is a combination of ideas and technology, where on its own, a single component of the puzzle would not work. Harvesting grain still requires two vehicles. The combine harvester sorts the wheat from the chafe, the tractor collects the grain and transports it so that the combo can keep on working. This is very much like the process that we are developing to be able to tackle the vast oceans and make headway. Combine technology has increased with ever larger rotating heads and cutters. These machines require enormous diesel engines, that would make harvesting plastic from the oceans unthinkable in fuel costs alone. The New Holland CR10.90 is the new world class of the harvesting community with a 16-liter, six-cylinder inline diesel engine pumping out a massive 652 horsepower (486 kW) to fill a 14,500 liter grain storage tank - or 11.15 tonnes (metric tons).

The Seavax and Combine harvesting concepts, thus, have quite a bit in common. Both concepts require a machine to ingest a product on a large scale, filter it and store it for collection by another machine. Both concepts need as large a head as is practical, to speed up the harvesting process, or reduce the number of passes - which, amounts to the same thing. The big difference is that one system operates on land and the other water. SeaVax, is a completely new combination of ideas as of December 2015, starting with a clean sheet of paper. Energy autonomy has been identified as a prerequisite, much as being unmanned is also a huge operational cost benefit.

SAFETY SCREENING

We don't want animals such as fish or mammals entering the system. That means installing sensors and warning systems, and finally, if an animal ignores such admonition, a shut off fail safe. Unavoidably, some smaller organisms will get through and may become a casualty of ocean waste, the design brief is to keep potential casualties to an absolute minimum.

This world map derived from a National Geographic source, shows that the North Pacific Gyre is by far the largest - and divided into three regions, the western, sub-tropical-convergence zone and eastern garbage patches. We estimate these patches collectively to be around 100,000 - 80,000 tons in mass.

Youtube ocean pollution

From the maps of the ocean in our plastic ocean features, it is obvious that the worst affected region is the ocean that circles between Asia (Japan) and North America. Click on the title above to learn more.

Our love affair with plastic is choking the oceans. Once people know about it, they want to stop it. But how? The next question is who? Obviously, if any of the researchers involved so far had come up with a solution, they would have sorted it years ago. We are a practical think-tank fresh to the issue and without a budget. We hope to be able to collaborate with other marine organisations that are funded for this work, or who have funds to investigate viable projects. You cannot donate to us directly on this site, but we hope to identify partner sites shortly where you can support a project much like that proposed herein, or better still, our own practical experiments. Volunteer careers.

LINKS

Waste Management World waste-to-energy-industry-welcomes-consultation-on-plastic National Geographic 2014 ocean garbage patch plastic pacific debris The Telegraph Great Pacific Garbage Patch has increased 100 fold since the 1970s Plosone ocean pollution article Fjournal pone 0111913 The Guardian 2014 December full scale plastic worlds oceans revealed first time pollution Robotics Tomorrow ocean pollution Daily Dot technology ocean cleaning drone Interiorholic gadgets ocean robot cleaner PSFK 2012 marine robots clean oceans IB Times giant-vacuum-cleaners-artificial-rain-china-gets-creative-pollution-clean Fast Coexist James Dyson is designing a giant vacuum on a barge to clean ocean trash Kumu 2013 those crazy men and their plastic cleaning machines vafusa hydrocyclone separators Vortex depollution products shredders pet bottle perforator http://www.vortexdepollution.com/products/shredders/shredders/pet32-perforator http://www.forrec.eu/dual-shaft-shredders http://www.machinerydata.com/PlasticLumber.htm http://www.ksb.com/giw-en/ http://www.hydrocyclone.com/ http://en.wikipedia.org/wiki/Hydrocyclone https://www.vafusa.com/hydrocyclone-separators.htm http://kumu.cc/2013/03/27/those-crazy-plastic-cleaning-machines/ http://www.dyson.co.uk/community/james-dyson-foundation.aspx http://www.dyson.co.uk/ http://www.ibtimes.co.uk/giant-vacuum-cleaners-artificial-rain-china-gets-creative-pollution-clean-1433926 http://www.unep.org/ http://www.unep.org/environmentunderreview/ http://news.nationalgeographic.com/news/2014/04/140414-ocean-garbage-patch-plastic-pacific-debris/ http://www.plosone.org/article/info%3Adoi%2F10.1371%2Fjournal.pone.0111913 http://www.roboticstomorrow.com/content.php?post_type=1919 http://www.dailydot.com/technology/ocean-cleaning-drone/ http://www.interiorholic.com/other/gadgets/ocean-robot-cleaner/ http://www.psfk.com/2012/07/marine-robots-clean-oceans.html http://www.unep.org/environmentunderreview/

ARCTIC - ATLANTIC - BALTIC - BERING - CARIBBEAN - CORAL - EAST CHINA - ENGLISH CH - GULF MEXICO

INDIAN - MEDITERRANEAN - NORTH SEA - PACIFIC - PERSIAN GULF - SEA JAPAN - STH CHINA

PLASTIC BRITAIN - PLASTIC OCEANS

|

||||

|

This website is Copyright © 2015 Bluebird Marine Systems Ltd. The names Bluebird™, Bluefish™, SeaNet™, SeaVax™ and the blue bird and fish in flight logos are trademarks. CONTACT US The color blue is a protected feature of the trademarks.

|