|

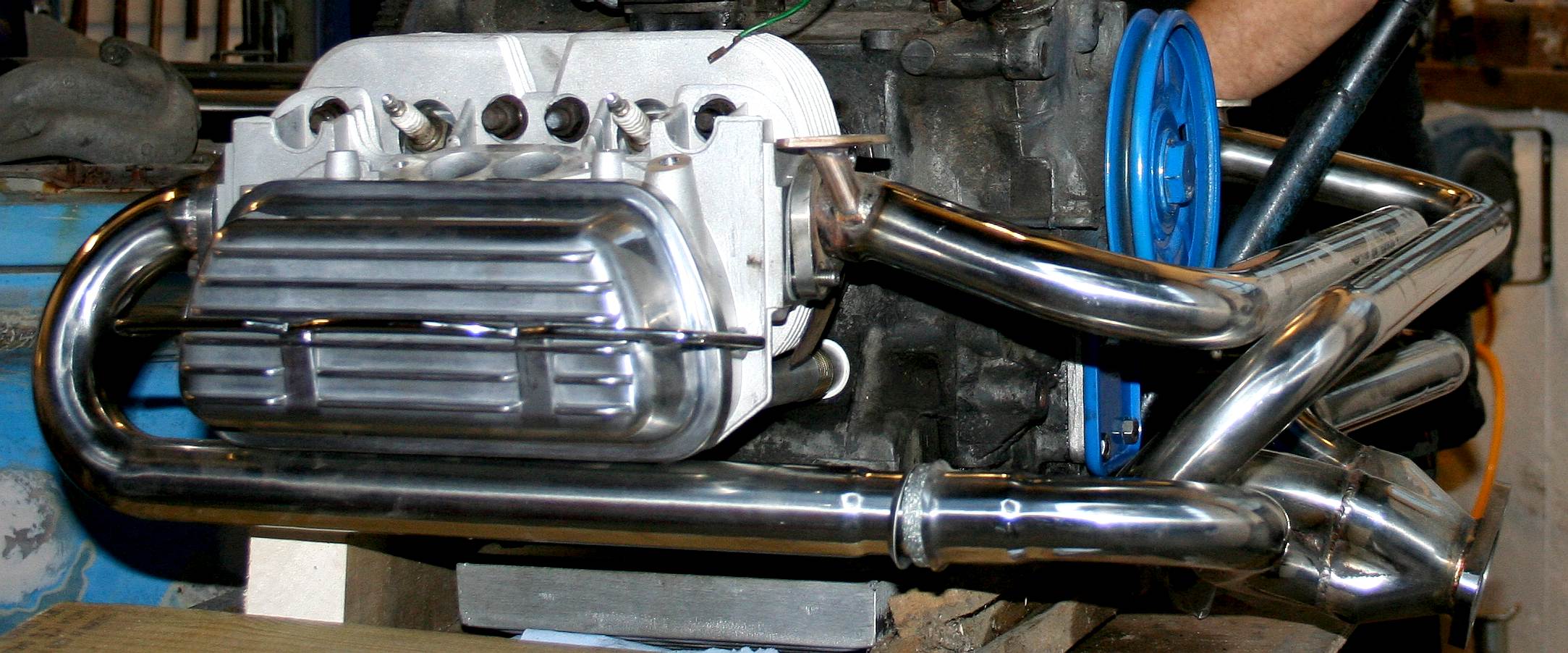

ENDURANCE

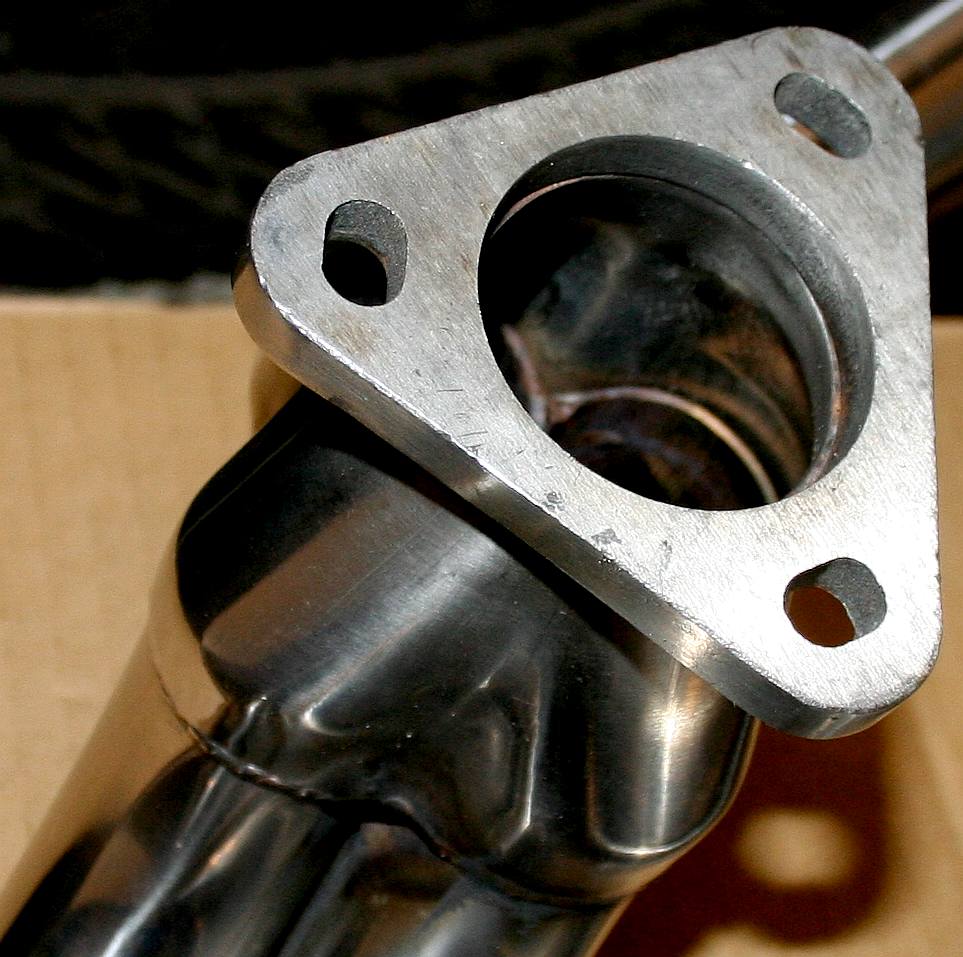

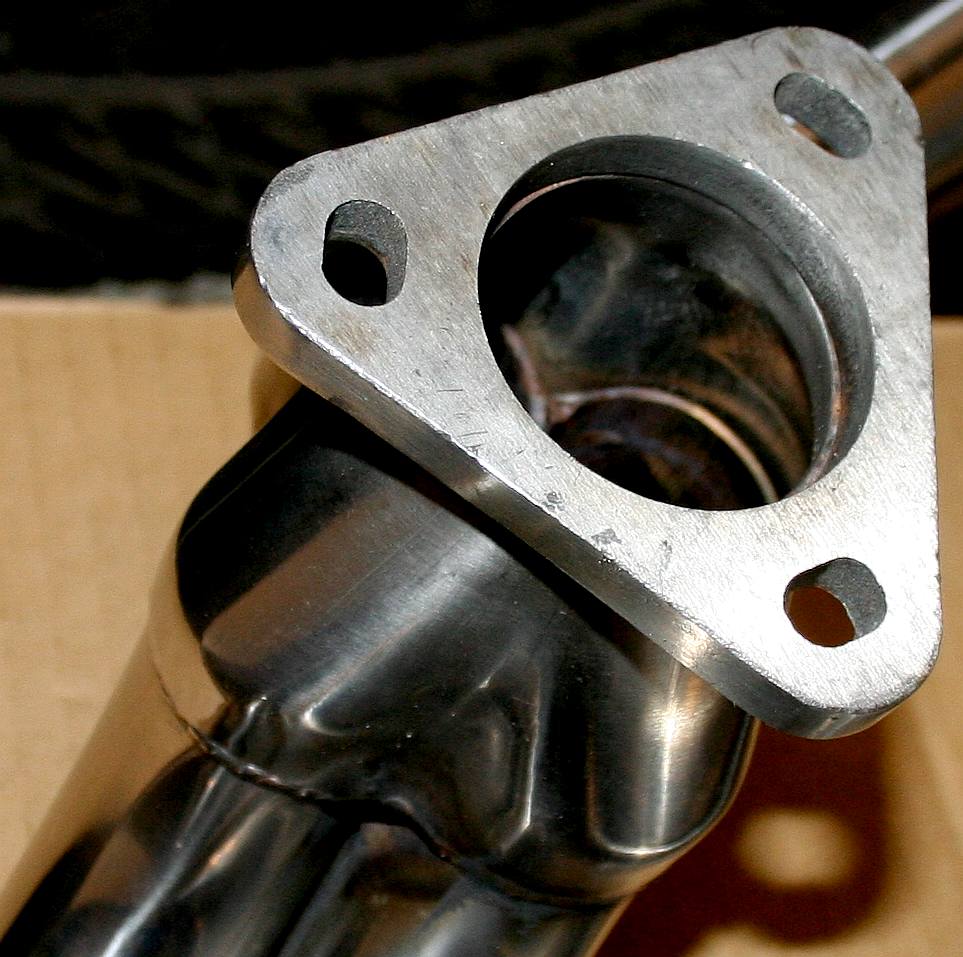

PARTS - This is the manifold of one of the quieter sporty exhaust

systems that you can fit to a type 2. All four pipes lead to this flange,

onto which is bolted the silencer. Copyright photograph 30 November 2016

Bluebird Marine Systems Ltd, all rights reserved. You will need the

permission of Bluebird Marine Systems Ltd to reproduce this picture except

for media review or private research, or educational purposes.

Stainless

steel is not only nice

to look at, but it does not rust in open air conditions where

water makes

short work of ordinary steel. The discovery was made by accident when a metallurgist

noticed that a high chromium content alloy that had been discarded had not

rusted when on the scrap pile.

There are different types of stainless steels: when nickel is added, for instance, the austenite structure of iron is stabilized. This crystal structure makes such steels

virtually non-magnetic and less brittle at low temperatures. For greater hardness and strength, more carbon is added. With proper heat treatment, these steels are used for such products as razor blades, cutlery, and

tools, but they are difficult to drill with an ordinary high speed steel

tool.

Significant quantities of manganese have been used in many stainless steel compositions. Manganese preserves an austenitic structure in the steel, similar to nickel, but at a lower cost.

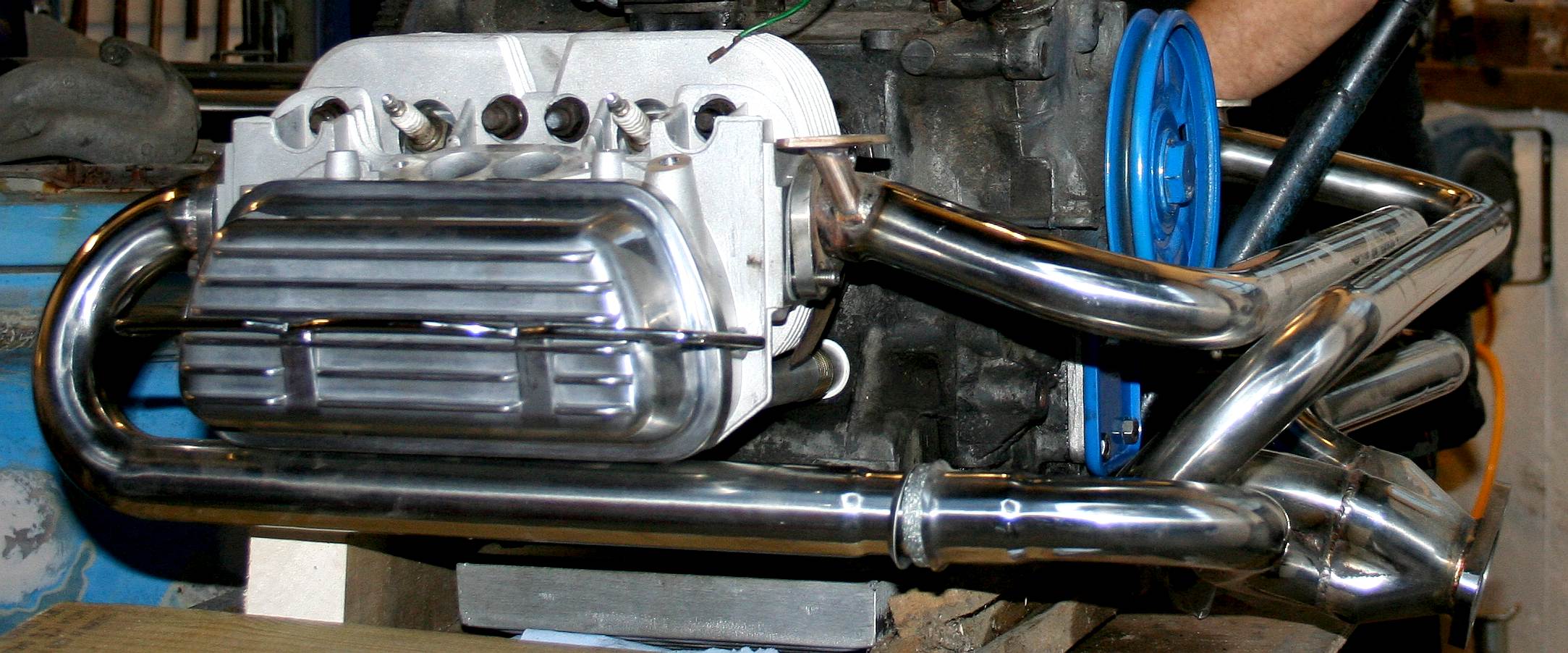

'J'

PIPES - This kit came almost complete with all the parts you need to fit

and forget the ductwork for the burnt gasses that exit your air cooled lump

at the rate of 1,600 litres @ 2,000 rpm. This is not taking into

consideration expansion of the combusted mixture that is of course

compressed and trying to escape into the atmosphere to contribute to climate

change. Copyright photograph, 30 November 2016, all rights reserved. You

will need the permission of Bluebird Marine Systems Ltd to reproduce this picture.

SILENCE

- This is the part that absorbs most of the sound energy caused by exploding

fuel in a confined space. Copyright photographs, 30 November 2016, all rights reserved. You

will need the permission of Bluebird Marine Systems Ltd to reproduce this picture.

HEADERS

- On any other engine these would be called headers, but because each cast

iron cylinder has a single pipe coming from a different angle and direction

to the other three pipes, there is no conventional cast iron exhaust

manifold. Copyright photograph 30 November 2016, all rights reserved. You

will need the permission of Bluebird Marine Systems Ltd to reproduce this picture.

NOT

BAD LOOKING - Not only will this exhaust system last a bit longer than

the original mild-steel counterpart, but it also improves the performance of

the engine. Copyright © photograph 1 November 2017, all rights reserved.

METALLURGY In metallurgy, stainless steel, also known as inox steel or inox from French inoxydable (inoxidizable), is a steel alloy with a minimum of

10.5% chromium content by mass.

Stainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.

Stainless steel is also used for corrosion-resistant tools for surgical

operations.

Stainless steel does not readily corrode, rust or stain with water as ordinary

steel does. However, it is not fully stain-proof in low-oxygen, high-salinity, or poor air-circulation environments. There are various grades and surface finishes of stainless steel to suit the environment the alloy must endure. Stainless steel is used where both the properties of steel and corrosion resistance are required.

Stainless steel differs from carbon steel by the amount of chromium present. Unprotected carbon steel rusts readily when exposed to

air and moisture. This iron oxide film (the rust) is active and accelerates corrosion by making it easier for more iron oxide to form. Since iron oxide has lower density than steel, the film expands and tends to flake and fall away. In comparison, stainless steels contain sufficient chromium to undergo passivation, forming an inert film of chromium oxide on the surface. This layer prevents further corrosion by blocking oxygen diffusion to the steel surface and stops corrosion from spreading into the bulk of the metal. Passivation occurs only if the proportion of chromium is high enough and

oxygen is present.

Stainless steel’s resistance to corrosion and staining, low maintenance, and familiar lustre make it an ideal material for many applications. The alloy is milled into coils, sheets, plates, bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipment (for example, in sugar refineries) and as an automotive and aerospace structural alloy and construction material in large buildings. Storage tanks and tankers used to transport

orange juice and other

food are often made of stainless steel, because of its corrosion resistance. This also influences its use in commercial kitchens and

food processing plants, as it can be steam-cleaned and sterilized and does not need paint or other surface finishes.

CONCERT

HALL

- This is the Walt Disney concert hall in Los

Angeles, California.

3D

PRINTING Some 3D printing providers have developed proprietary stainless steel sintering blends for use in rapid prototyping. One of the more popular stainless steel grades used in 3D printing is 316L stainless steel. Due to the high temperature gradient and fast rate of solidification, stainless steel products manufactured via 3D printing tend to have a more refined microstructure; this in turn results in better mechanical properties. However, stainless steel is not used as much as materials like Ti6Al4V in the 3D printing industry; this is because manufacturing stainless steel products via traditional methods is currently much more economically competitive.

AUTOMOTIVE

The Allegheny Ludlum Corporation worked with Ford on various concept cars with stainless steel bodies from the 1930s through the 1970s to demonstrate the material's potential. The 1957 and 1958

Cadillac Eldorado Brougham had a stainless steel roof. In 1981 and 1982, the

DeLorean DMC-12 production automobile used Type-304 stainless steel body panels over a glass-reinforced

plastic monocoque. Intercity buses made by Motor Coach Industries are partially made of stainless steel. The aft body panel of the

Porsche Cayman model (2-door coupe hatchback) is made of stainless steel. It was discovered during early body prototyping that conventional steel could not be formed without cracking (due to the many curves and angles in that automobile). Thus,

Porsche was forced to use stainless steel on the Cayman.

MARINE

- MARITIME JOURNAL 19 JULY 2017

It is easy to see the attraction of using stainless steel as a building material for boats because of the lack of corrosion problems and reduced maintenance during the life of the boat. However there are downsides, one of which of course is the higher cost of the material.

When they were developing a new high performance patrol boat design, Swedish Steel Yachts (SSY) decided to build the vessel’s hull from stainless steel. This was a major step forward in

patrol boat construction and now with the boat completed Rickard Levin of SSY has looked at the benefits and the problems that developed from using this innovative material. Using stainless steel for hull construction is not new but to use it for a high performance craft is a step into the future.

Project P16 is Swedish Steel Yachts’ prototype of an offshore patrol vessel which has a hull constructed entirely of stainless steel for demanding use. The stainless steel used was supplied by Outokumpu, based in

Finland and is their Forta SAF 2507 type which was selected because it is a material noted for its durability and strength.

The hull design is based on a deep vee hull with a short vertical stem that helps to reduce the overall length without compromising the performance. It features a low set pilot house with the bottom of the forward sloping windows flush with the top of the coachroof. There is a low aft cockpit over the engine compartment.

Levin says that the stainless steel for the vessel was a small part of the overall cost, around 2% of the total cost although the sheet metal itself is probably twice the cost of matching

aluminium. “The SAF 2507 alloy is strong and has extraordinary properties regarding resistance to corrosion in all maritime environments”, said Levin.

CHROME

SHINE

- The stainless steel may not need antifouling on the exposed undersurfaces,

whereas algal growth typically fouls painted surfaces. The problem here

being that a full-on polished stainless steel hull would look out of place

in military use.

Comparing aluminium to the stainless steel, Levin commented, “First the amount of weld. As the weld is generally the weakest part of

aluminium construction the thickness of the weld has to be large. This is due to the material in the weld going back to its elemental properties after welding. Using a thick

weld for aluminium takes longer than a thin one. Secondly the

aluminium is way weaker than the stainless steel which means that a denser framework of sections and longitudinal stiffeners has to be used. This increases the amount of welding.”

When welding the stainless steel used for the P16 it requires a ‘root gas’ during the welding process. This means that for some areas there has to be a welding assistant applying the gas from the back which increases the cost. Polishing the

weld can be done mechanically for both types of material and overall the welding crew considered that the cost of welding the stainless steel structure was comparable to that for a similar aluminium hull.

There were some challenges in the fitting out of a stainless steel structure. Drilling is difficult, requiring special drill bits and constant cooling and lubrication so even a single hole takes some time. As many holes as possible were pre-placed so that they could be cut when the stainless sheets were laser cut. The same problems were found with grinding and cutting. Bending of the plates is also difficult and larger machines were required to handle the loads. The design also had to be developed to eliminate

welding on flat topside surfaces as far as possible as these are made from thin plate that easily buckles from the heat of

welding.

SSY has patented this method of construction and aims to offer this patrol boat design as a standard for use by customs, the military, law enforcement and similar high speed patrol duties. The big benefit of using stainless steel for the construction is that the maintenance is greatly reduced and it is claimed that the hull does not require anti-fouling paint although the above water sections may require paint for cosmetic purposes.

The overall length of the P16 is 17.1 metres and the beam is 3.99 metres with the lightship weight being 16 tonnes. The hull deadrise is 24° to give a well cushioned ride.

The prototype is powered by a pair of 858 kW DI16 XPI 076M Scania diesels which are close couple to the MJP

water

jets. These jets are of type DRB 350 and the combination makes for a compact engine room installation. The top

speed is quoted as in excess of 47

knots which was the contract speed and the boat reached a speed of 53 knots when on trials at a weight of 18 tonnes.

The fuel consumption is 200 litres per hour when cruising at 37 knots and at this speed the P16 has a range of 500 miles. Humphree interceptors are fitted at the transom and these can be set in automatic mode to trim the hull to suit the conditions, to reduce the pitching motions and to provide a coordinated turn.

The pilothouse is constructed from carbon fibre to reduce weight and it is

rubber mounted to improve the comfort levels for the crew. The boat is designed to operate with a two man crew with the helmsman’s sprung seat located on the centre line. Further seating can be arranged in the pilothouse to suit requirements. The

electronic outfit has been supplied by

Raytheon and can be specified to meet requirements.

Fuel is carried in two tanks under the pilothouse. The rest of the hull interior forward can be fitted out as required with accommodation or storage. An

inflatable tender can be carried on the aft deck with a sloping section incorporated into the aft deck area to facilitate

launch and

recovery.

This new design in stainless steel will be watched with considerable interest in the commercial and military sectors as this construction material could offer significant long term benefits.

By Dag Pike

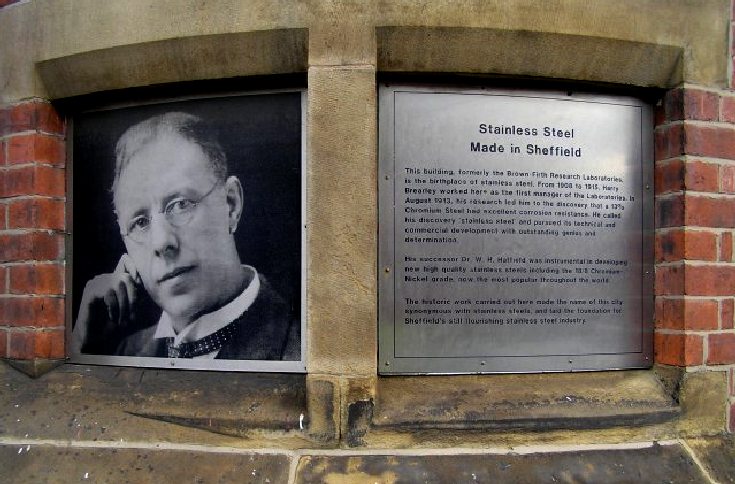

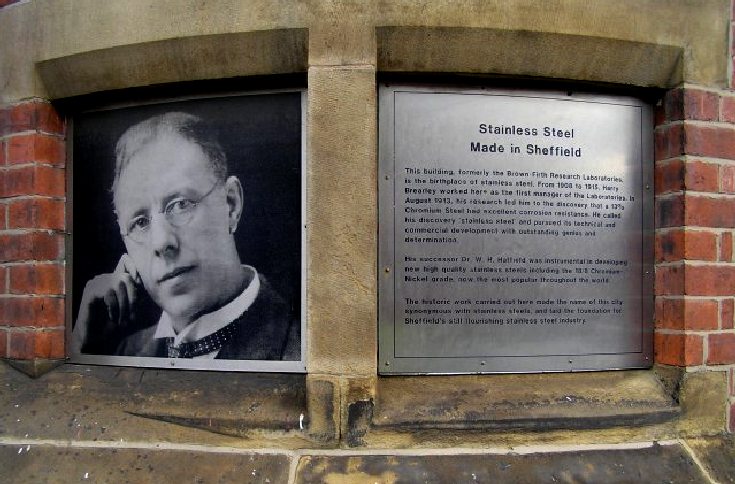

HISTORY

In 1912, Elwood Haynes applied for a US patent on a martensitic stainless steel alloy, which was not granted until 1919.

In 1912, Harry Brearley of the Brown-Firth research laboratory in Sheffield,

England, while seeking a corrosion-resistant alloy for gun barrels, discovered and subsequently industrialized a martensitic stainless steel alloy. The discovery was announced two years later in a January 1915 newspaper article in The

New York

Times. The metal was later marketed under the "Staybrite" brand by Firth Vickers in England and was used for the new entrance canopy for the Savoy Hotel in

London in 1929. Brearley applied for a US patent during 1915 only to find that Haynes had already registered a patent. Brearley and Haynes pooled their funding and with a group of investors formed the American Stainless Steel Corporation, with headquarters in Pittsburgh, Pennsylvania.

In the beginning stainless steel was sold in the US under different brand names like "Allegheny metal" and "Nirosta steel". Even within the metallurgy industry the eventual name remained unsettled; in 1921 one trade journal was calling it "unstainable steel". In 1929, before the Great Depression hit, over 25,000 tons of stainless steel were manufactured and sold in the

US.

STAINLESS

STEEL LINKS

http://www.uksteelcentre.com/

http://www.uksteelcentre.com/

http://www.icifonderia.com/en/

http://www.ebay.com/sch/Brighton-Stainless-Steel-Fashion-Jewelry/10968/bn_2022011/i.html

http://www.screwfix.com/c/screws-nails-fixings/stainless-steel-screws/cat7270018

http://www.aalco.co.uk/products/stainless-steel.aspx

http://www.bssa.org.uk/

https://en.wikipedia.org/wiki/Stainless_steel

http://www.r-techwelding.co.uk/

http://www.alanhschofield.com/

https://www.vwheritage.com/

http://www.coolairvw.co.uk/

http://www.justkampers.com/

http://www.volkszone.com/

http://www.volkswagen.co.uk/

ARCHES

- VW

HOME - BODYWORK

- ENGINE

- GOLF - LOGISTICS -

STAINLESS

STEEL

- SUSPENSION

& BRAKES - VINYL

WRAPPING - WELDING

|