|

ECOSTAR DC50 SPECIAL

Electric City Sports Car

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OCTOBER 2014 STANDSTILL - Realizing that funding for the concept was a pipe dream, we relegated development to the slow lane. The world's most versatile EV design now sports skirts at the front and rear. The challenge for the ECOSTAR DC50 (Direct Current motors and 50kW) special, is to reduce the long standing 80 second recharging world record, to less that 30 seconds. We know it is possible to get this down below 10 seconds. At present we have no budget for technology that challenges IC engines and fast charge - essential though that may be for a truly circular economy - it is innovation that is too far ahead of its time to be considered a good commercial risk. We are an R&D company that maybe should have an academic constitution. We are not yet a trading concern or manufacturer.

ON ICE, JANUARY 2016 ± 2019 - One day we hope the political will might be with us - when (if the funding rules change dramatically) you can watch this car turn into a motoring gem, as it rises like a Phoenix from the ashes. We are a non-trading company in waiting. If we'd been a university we would have been eligible for 100% funding and this car would have been exhibited and written about such that all world leaders could see the potential. Disruptive technology like this should be state funded, not for SMEs to risk all - as we say - swimming against current thinking.

STOP PRESS: WITH LITTLE OR NO POLITICAL WILL AND OTHER MATTERS PRESSING, WE PLACED THIS PROJECT ON HOLD IN JAN 2016 - IN FAVOUR OF SEAVAX.

SEAVAX HAS NOW BEEN PASSED TO ANOTHER ORGANIZATION. WITH RENEWED INTEREST ON THE PART OF THE EU AND UK, WE HAVE RE-ACTIVATED THE SERVICE STATION CONCEPT AS: SMARTNET

WHERE WOULD WE HAVE STARTED? - It's a chicken and egg situation with EVs needing service stations and service stations needing EVs they can service. Fast charge is not the answer for a truly sustainable society. Fast charge systems damage batteries and put a strain on generating networks, creating peak times when more generating capacity will be required. Motorists don't like the idea that they have to wait so long for energy. The wait instills "range anxiety" in EV users where they are constantly looking at their charge meter and planning for the next stop - for another long wait while their vehicle fast charges. Yet, this is one potential cure for Climate Change, a hot topic at the COP21 talks in Paris in December 2015.

THE CURE - Actually, one cure - there must be others - is a vehicle that exchanges energy cartridges itself using built in loaders. The car then becomes the EGG and the CHICKEN.

* It is the EGG because it creates a need for service stations while serving itself meantime.

* It is also the CHICKEN, because the cartridges that need to be charged creates a need for service stations. That is enough on this subject. This page is about building the car, not the service station - though we'd love that.

A BLUE BIRD IN WAITING - In storage and under cover in a temporary display case that is also a solar powered car park for when this lovely little sports car can come out to play a part again. If the UK plan to have electric cars with a suitable support infrastructure in place is ever to see the light of day, the many stakeholders could do a lot worse than incorporate solar charging and built in battery exchange for a truly circular economy. We feel sorry for the oil companies. There will be no place at the Inn for those who fail to adapt in time. BP, Shell, Amoco, Texaco and others look set to enter an ice age with not very long to pump as much oil for maximum short term profits for their shareholders as they can squeeze from that particular lemon. The electric revolution is coming. We know from driving our BMW i3 to and from events how beautiful and practical that is going to be. All the Dti need to do is incentivise the up and coming innovators of the future sufficiently - and not do what they did to us - which was to effectively, to make us look for greener pastures.

This photograph is used under license with thanks. Copyright © Lime Park Heritage Trust, 20 August 2017 all rights reserved. You will need the permission of the copyright holders to be able to use this picture, save for private study and educational use.

EDF PULSE AWARDS - NEWS FEED 2016 CONFIRMED OUR DECISION TO FREEZE PROJECT WAS THE RIGHT ONE.

VEHICLE DESIGN CONSIDERATIONS - If you are new to car design, this is the all important question - what are you trying to achieve? How are you going to achieve it and with what?

Most young engineers want to build something fast. Most middle aged engineers want something comfortable and sporty but have one eye on running a family. Retired engineers want comfort and reliability. What then are you trying to achieve. Once you know the answer to that you can begin to put a shopping list together.

OUR BRIEF - Our task was simple. Using what was already in stock, come up with an eco car that could beat the current record for driving from one end of the Kingdom, to the other. The record to beat was/is 36 hours. So we need a car that can travel 894 miles in less than 30 hours. Why 30 hours? Well, if you are trying to beat a record, you should aim to beat the old record by at least 15%, so that gives us 30 hours. 30% would be better, bringing the target time down to 25 hours.

That is of course easy-peasy in any petrol car - so not even a challenge. That equates to 39 miles per hour average. The total distance might be covered with just two stops at a petrol pump. But in an electric car range restriction is the thing to beat. With average charging time being hours not minutes, all of a sudden it is not the speed of the vehicle that matters, it is how quickly we can recharge our car's energy banks. And that is where we started. We wanted to bring down the time to recharge with energy to under a minute.

What are your goals? Once you know what you want, it is much easier to think of a way to achieve it.

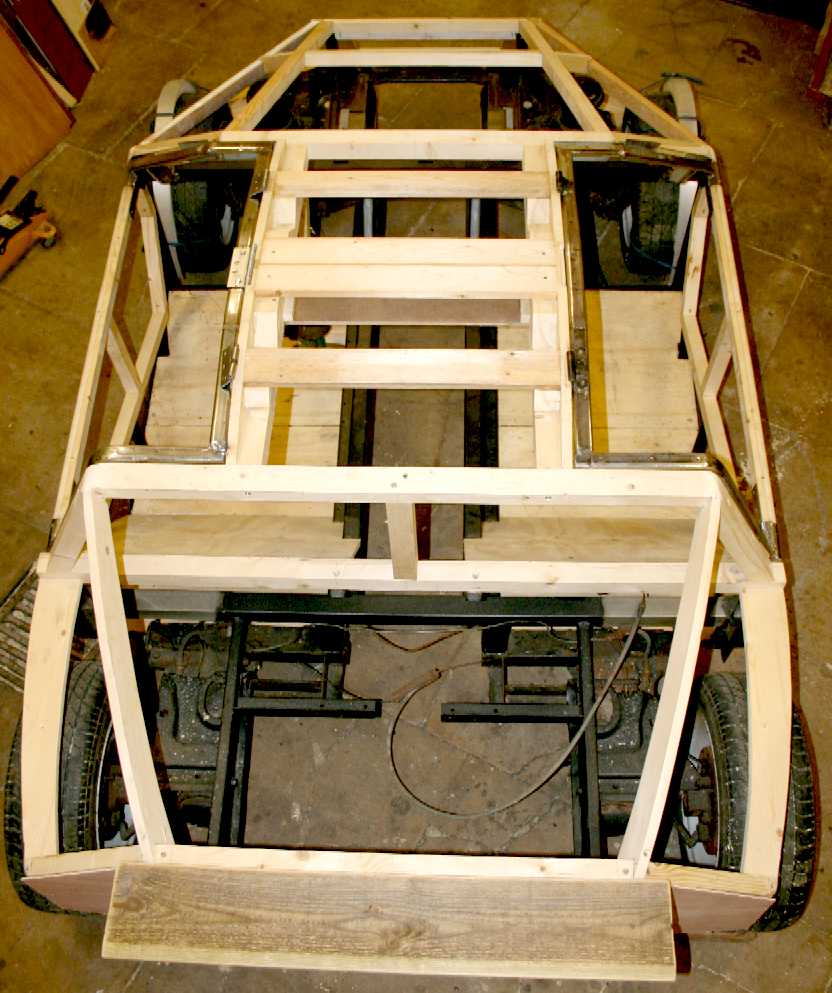

The ECOSTAR DC50 Special - This is what the car looked like in plan view after a couple of months (August 2014) getting the base mechanicals into some kind of order. We used timber to make a framework (coachwork) as the foundation for composite panels. Much of the timber in this picture will be replaced by carbon fiber, steel, or aluminium, especially the working surfaces. Compare the progress with the pictures below, taken when the project was just a seed taking hold. The team are aiming to have the mechanics and body of the DC50S completed in time for December the 31st, to be able to celebrate that event with a champagne toast to one of the most progressive adventurists the world has ever seen. Please note that these pictures are copyright © BMS 2015 and you will need our permission to reproduce them. We can supply higher quality for magazines, etc.

The ECOSTAR DC50 Special - This is what the car looked like from the front November 16 2014. Finally, foam sheets are being cut to shape the various body panels that will be carbon fibre. It's a messy affair, but very enjoyable when you can start to see your vision coming to life.

The door roof section on the left has foam shaped in rough, the door roof section on the right is just a foam blank ready to be fitted. The ally arches are screwed in place, ready to be folded on the outer edge to make a visually pleasing (and functional) rim.

Shaping of the nose and wings required a significant quantity of foam that needed to be slotted into place in jigsaw fashion. We are careful to ensure that plastic waste is disposed of responsibly.

Foam blocks are carved by an experienced craftsman, to achieve a near perfect shape using only hand tools. This technique is suitable for one off prototypes, but if we go into production, it is far too labour intensive - although Aston Martin and Morgan still produce the bodywork of their cars by hand. The wing on the left of this picture (offside in the UK) is nearing final shape. The right wing (nearside in the UK) is still 2nd stage boxy. Same with the roof panels of the gullwing doors. The offside is shaped, the nearside has yet to be carved. Please note that these pictures are copyright © BMS January 2015 and you will need our permission to reproduce them. We can supply higher quality for magazines, etc.

The Ecostar will look much like the Autocad drawing at the head of this page. She will carry solar cells, even though the UK is high latitude, this should bear fruit in sunnier climates. The above AutoCad plot is faithful to the new (actual built) roofline, which is Lancia Stratos like, in widening as it goes back. Does anyone remember that Bertone classic apparently due for a re-launch?

ECOSTAR DC50 LINKS A-Z INDEX

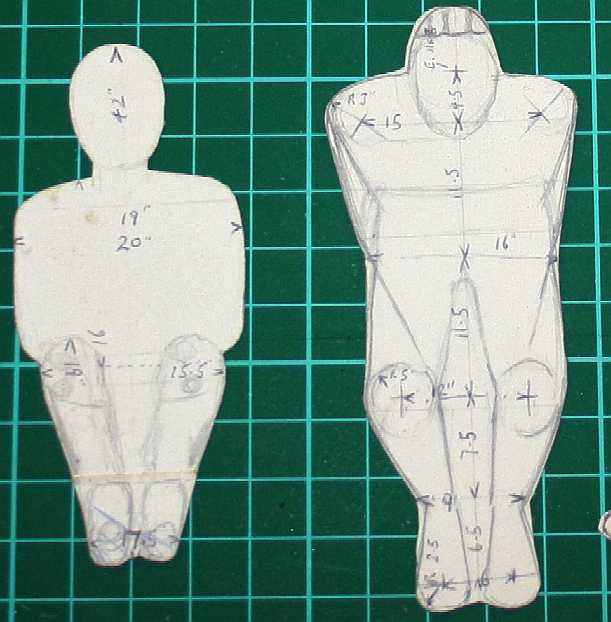

BACK TO BASICS - Where do I begin? Designers very often forget that the starting point for any car is the driver, followed by the passengers and cargo spaces. That's right, it is not the chassis, engine or suspension. That comes after you have decided on the speed (or economy) that your want to transport your driver/passengers, or payload, from point A to point B. In an age of computers and CAD, we still find it useful to have cardboard figures cut to scale, to move them around a model - to be able to visualize the head and leg room. The above are 1/10th scale figures seated in a typical car driving position. The bespoke dimension of this chap are clear, but allowances should be made for different shape drivers. Hence, when thinking of designing a car, get the tape measure out and measure yourself - then measure a few other people. Humans are all shapes, sizes and ages.

PROJECT HISTORY

Bluebird Marine Systems obtained the rights to a long-forgotten project codenamed "Tomcat" on February the 6th 2014. 'Tomcat' was a project to develop an electric sports car (presently based on Rover running gear). 'Tomcat' was also the project name for a Rover coupe, so please bear this in mind. There are a lot of projects out there with similar names. Ours is the only electric Tomcat, as far as we know.

BMS ramped up the electric Tomcat project in typical DC style, to incorporate brand new (higher performance) patent battery cartridge technology - for instant recharging and the ability to change from battery to fuel cell technology at the flick of a switch. Important where vehicle makers are hedging their bets as to what energy source to put in their electric cars.

SEED FUNDING - This project is at the moment funded by directors loans, also using stock and existing tooling. Labour has been generously donated by all our staff and the Speedace team members. This is the kind of spirit of cooperation that Donald Campbell relished.

Previously this chassis achieved battery cartridge exchanges (hence instant refueling) in under 80 seconds, using built in electrically powered loaders - meaning that the car supported itself infrastructure wise, unlike other cartridge exchange systems.

The ECOSTAR DC50 has seen a number of refinements and the process will continue. She is a two seat (city) sports car with front wheel drive and 50kW direct current (DC) electric motors. The roof will carry solar panels to charge the onboard battery cartridge as a range extender between instant recharging pit-stops. The cartridge may contain batteries, fuels cells, or a mix of batteries and fuel cells. The technology future proofs vehicles against battery and/or fuel cell advances. Whether to include, or not to include in new zero carbon vehicles, is a no-brainer.

WORLD RECORD

The car pictured here held the world recharging record at the time of construction - and so far as we know that record set in 1999 stands unbroken, a bit like Burt Munro's Indian Scout 45. The closest, at three minutes, was the Better Place system until Tesla lowered that to 90 seconds.

With our safer, low-voltage system, we are aiming for running costs equal to 100 + miles per gallon. The range of the car when fitted with a special transmission is likely to exceed 300 miles per cartridge exchange (or battery charge) and offer sporty performance. To begin with we will not be developing this transmission. This is a low budget research project that is suitable for funding under the Horizon 2020 scheme, or other local enterprise initiatives.

The ECOSTAR DC50, also known affectionately as the Tomcat (or project BE4) as there are a couple of friendlies patrolling the grounds, is to be powered by the famous Lynch DC motors to produce 50kW, hence the DC50 legend. The car may also be fitted with an onboard generator in the later stages of the project, turning it into a hybrid - also likely to return above 100 miles per gallon. This will provide a means of keeping going, where either battery exchange is not practical or where a convenient charge point is not to hand.

Unlike other fast energy transfer systems, only vehicles with cartridge exchange may swap between fuels at the flick of a switch. The versatility that this offers is truly the means to convert gently to a sustainable zero carbon transport system. Ideally, this would be coupled with our vision for low cost infrastructure support, which we would like to see phased in over the next 10 to 20 years. We would love to be in a position to undertake a feasibility study, then to be able to construct a working pre-production prototype.

The roof of the DC50 is to be fitted with solar panels to supplement the already comprehensive EV technology. The PV panels will give between 1,000-2,500 free motoring miles per year, depending on usage and geographical location. We operate on the south-east coast of England. Solar powered service stations are on our drawing board, that are KISS simple and cost effective.

ENERGY HARVESTING

Energy that is typically lost in a conventional vehicle, may be harvested for future developments of the 'BE' series of vehicles, to include piezo-electric generation from suspension vibration, shock absorbers and body parts, combined with smart energy trackers.

This may be achieved by replacing the existing hydrolastic suspension with suitably modified components. This could include piezo-electric chips embedded in the rubber cone compound.

By way of example, CEDRAT TECHNOLOGIES has developed several types of piezoelectric actuators displaying interesting properties for vibration and shock-energy harvesting. Among them, Amplified Piezoelectric Actuators (APA®) combined with mass operating are especially interesting piezoelectric generators. Cedrat may easily define customised piezo generators for vibration or shock-energy harvesting. We will bear this in mind should research funds materialize.

STRUCTURAL ENERGY STORAGE

Vehicle onboard energy storage may be enhanced by using body panels made from multifunctional materials, where the body has a battery embedded in the structure. The drawback here is time of charging, where changing car bodies is impractical. This may be overcome using solar and piezoelectric harvesting to charge the available additional capacity. This is though for later research.

Concept for a 7.68MW service station that can refuel 2 electric cars a minute. Five such stations could cater for a town the size of Eastbourne.

MASS ENERGY STORAGE - SERVICE FORECOURTS

There is hardly any point dwelling on Service Forecourts at this stage, but any good project manager thinks a hundred light years ahead at possible scenarios - and one such scenario is rather tantalizing. That is of course a means of storing energy for a hydrogen based European (World) community.

Our vision is that cartridge storage that is interchangeable between batteries and hydrogen, would give us as easy way to ask the public to invest in vehicles, that are in effect future proofed. It's a terrible decision that one has to make, such as investing in VHS or BETAMAX, and now DVD or BLURAY. How many times do we have to throw away a complete collection of films and re-purchase in another format.

Not so with the Bluebird™ service forecourts of the future, provided that you have bought a vehicle with compatible cartridges in the first place. (We say that because at the moment there is a competing system. There is always a competing system.) So, lets assume that you have purchased a vehicle with the Bluebird™ cartridge system - and for that we have to imagine that we have already developed that system - for that dinky little car above, then you can swap between storage mediums at no cost. How?

That is because with the Bluebird™ Pay As You Drive system, you don't own the cartridge you are using. You in effect hire it short term. This is the social business model that can make it work. It is called PAYD. We will reveal more on this, should we achieve funding to carry out a feasibility study.

Two basic concept designs for a Universal energy cartridge, both with 8 cubic feet of storage capacity. It is not so much the shape of the cartridge, it is that the ends are compatible with the car and any eventual service station. The pick-up and contact point details are not shown here due to patent laws prohibiting advance publication. Any shape cartridge may be suitable for a Bluebird™ service forecourt, provided that the basic "Universal" dimensions are adhered to. We will release these details one the applicable patent is in the processing pipeline. For any production car, we'd like to change the shape to a low profile design that is wider - still using the Universal connections of course.

ECOSTAR DC50 CITY SPORTS CAR STATISTICS

The basic layout of the Ecostar DC50 provides a near perfect weight distribution from a front wheel drive car. This is ideal for nipping around city streets, yet with racing car handling should you need it. The cartridge (in this case shown with batteries as the energy storage medium) is low, keeping the center of gravity well below that for conventional sports cars. In this Autocad generated diagram, you can see the built in electrically powered loading mechanism in turquoise. Click on the picture to read more about the mechanics of this car and how we aim to cut charging time to around 30 seconds without frying batteries. With a flatpack loading design, the boot space is not affected - what little is available with any sports car body.

Simplicity and integration are very important factors when designing an electric car that is able to support itself during energy cartridge swaps. The Ecostar DC50 is only the second road car in the world to have such a feature. In all other EVs with battery exchange as a range extender, the battery is loaded into the vehicle by external means.

Long forgotten as a range extender, when correctly set up a fluid interlinked front and rear suspension (axles) smooth out the ride of the main mass of the vehicle such that is does not change direction, hence lose the invested kinetic energy when negotiating bumps in the road. This is one of the main reasons that the Rover Metro was chosen as a donor vehicle, made possible by the sterling efforts of two of the greatest British design engineers: Sir Alex Issigonis and Dr Alex Moulton.

A mock-up jig of the hard-points for the bodywork using anything laying about in the garage. From this visual exercise we know that the roof can be formed from one sheet of aluminium - and that the profile is not that far from the curve described in the lead pictures above. The objective of the profile is to reduce air resistance. In a short car such as this, there will be no long streamlined tail. Instead, the tail will be truncated, ending in as small an exit cross-section as possible - commensurate with practicality. The Ecostar is turning into a rugged little beastie. We can't wait to see the gull-wing doors fitted. May 2014

The coachwork of the Ecostar will be made from a mixture of hand formed aluminium sheet metal and composite moldings. One of the most difficult areas of design for a one-off prototype body is the glass. This is because making a windscreen for one vehicle is very expensive. For that reason, flat screens are normally employed, from where the challenge is to make the car look stylish, while keeping good visibility. The frames used to form the body panels and roof are for the most part made of wood.

The Ecostar eco car, sits under a protective canvas cover at night, a gift from a local Sussex lady (and sun worshipper) who is an artist and loved the idea. Artists, of course, must express themselves. We are grateful for her support and enthusiasm.

This is the first road car to use our blue bird trademark. See how the bonnet and steering wheel badges were hand crafted by clicking on the left picture - and how it looked while the bodywork was being crafted, by clicking on the right picture.

Development of the radiator grille for our blue bird motif is a challenge for any artist. Next time you are out and about, take a look at all the fancy car radiator designs. A radiator and filler cap were functional items needed for the cooling system of IC engined cars. The radiator cap became the subject of much styling, eventually turning into the famous chrome Jaguar adorning many bonnets from, which art replaced the radiator cap; since radiators were no longer visible. The Rolls Royce Spirit of Ecstasy (flying lady) is another tradition from a bygone age. Mercedes have very nicely integrated their chrome star motif into most of their radiator grilles, making a feature of it, where that too was previously atop a radiator filler cap. Note the chrome bird on the Bentley radiator filler cap above, right. BMS now own one of these. Electric cars don't have radiators, but still need to cool motors.

DESIGN BLUES

Back in 1995 the UK led the way with EV refueling and patent GB2253379. Since that time Shai Agassi in the US had developed cartridge refueling for urban vehicles with his 'Better Place' company. That system though, requires heavy infrastructure support and is not suitable for the fast pit stops (for example) that a Formula E car is likely to require.

Bluebird Marine Systems (BMS) is looking to conduct a feasibility study on high speed cartridge refueling and is seeking collaborative risk share partners and/or academic institutions interested in reducing pollution, that might eventually lead a bid for European development money - or, maybe the other way round. BMS has secured the rights to develop an improved version of the patent GB2253379 system, written off many years ago by the Dti in 1998, in dismissing battery electric cars as futile. It just shows how blind to the real world, Government assessors can be if they try - but we'll not dwell on that. We are sure that the buffoons who made such declaration have long since been replaced (or at least we hope so), with their professional predictive powers in tatters. If only investment bankers will now change their rules to help budding entrepreneurs develop high risk disruptive technology. Dream on. Disruptive technology is at the bottom of their investment agenda.

In 1995, Powergen were supportive of this technology, just before they also decided to cancel their EV investment programme. Powergen of course, no longer exists. If they had backed this technology a little sooner, they might still have been in business. One good thing that Powergen did before their cremation, was to invest in the superb motors that we are still very fond of, by supporting Cedric Lynch with a cash injection. The Lynch motor is currently manufactured by Agni Motors.

LANDS END to JOHN O'GROATS - To demonstrate the system, a drive across the UK from John O'Groats to Lands End - in record time, will end the myth that EVs cannot compete with petrol cars as to range. The Ecostar DC50 has been made available to a UK team headed by Chris Close and Terry Valeriano - for this attempt. See below for details of other exciting ZEV runs around the world.

WELDING

One of the most basic skills when customizing any vehicle is the ability to join metals. Sometimes it is an advantage to rotate the work piece to get perfect welds; in this case the whole car has been turned on its side as you can see in the pictures on this page. Once adjustments are made to convert the vehicle to a two-seater, which includes welding in two floor-pan frames with bracing; the whole chassis will be shot blasted, primed and painted. We will feature more of the process for those interested in car design and development, as the project progresses.

The rules for the new series of Cannonball international ZEV runs say that you must use production vehicle running gear. Another pointer here is to choose a vehicle that is as simple and as light as possible. The frame of the Ecostar ZEV Cannonballer uses ordinary Austin Metro running gear, itself based on the genius of Sir Alec Issigonis, designer of the Mini.

CAR KITS

Dependent of demand, there is some prospect of producing chassis/body kits so that you can build your own electric and hybrid variants of the Ecostar. BMS are talking to a Chinese car maker who may in 5-7 years time, be able to supply a production DC50 for Europe.

Accessories such as the powered door rams above, will add a touch of elegance to any car with gull wing doors.

THE ORIGINAL SMALL CITY CAR

1959 saw the launch of the Mini with an initial production run of 20,000 cars priced at £496. In 1957 Alec Issigonis and his team at the British Motor Corporation (BMC) were charged to combat the increasing imports of inexpensive bubble cars from Germany and Italy, with a cheap, fuel-efficient, four-seater vehicle using an existing engine - to regain market share for BMC. This was called Austin Design Office Project 15 (ADO 15). Sir Alec would have liked the simplicity of the conversion above, if he'd been given the opportunity to work on electric vehicles. Sir Alec Issigonis did not invent the the mini-car formula but he became the creator of the most famous example. The Mini benefited from Issigonis’ collaboration with Alex Moulton and his rubber suspension system developments.

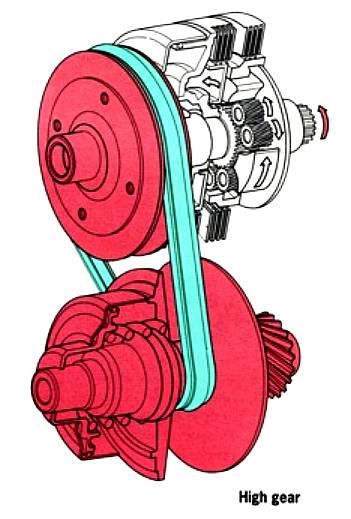

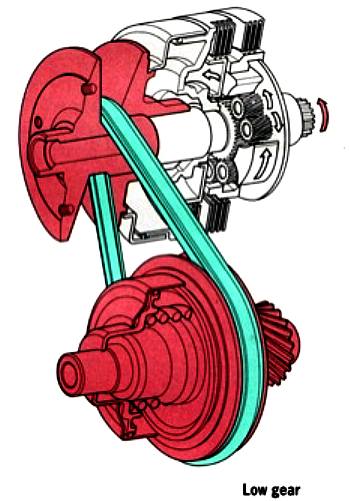

This is the Constantly Variable Transmission (CVT) from a Rover Metro. A gear-train like this is ideal for an electric vehicle. Once again, such promising technology shelved. The car’s design with its front wheel drive and independent suspension provided good road handling. The combination of the Mini’s design features and its safe handling suited competitive events. John Cooper transformed a car into the competition winning Mini-Cooper. James Hunt, Jackie Stewart and Niki Lauda started their racing careers in Mini-Coopers. The Mini became the best-selling car in Europe to become an icon of the 1960s. The car’s most celebrated media moment was its use as a getaway vehicle in The Italian Job, a movie from 1969 starring Michael Caine.

Compare the Suzuki Alto and Nissan Leaf specifications with the Ecostar DC50

If Lady Penelope had one of these she'd paint it the same color as her futuristic Rolls Royce and call it her Pink Panther.

OFFICIAL CANNONBALL INTERNATIONAL ZEV ROUTES

LINKS & REFERENCE

UK Government 75 million to build cars of the future South east local enterprise partnership https://www.gov.uk/government/news/75-million-to-build-cars-of-the-future http://www.southeastlep.com/ http://en.wikipedia.org/wiki/Alec_Issigonis http://www.greencarreports/historic-electric-vehicle-foundation-set-up-to-preserve-car http://www.wired.com/autopia/2008/02/giugiaro-builds/ http://www.horizonhydrogeneenergie.com/ http://www.fch-ju.eu/news/new-website-programme-horizon-hydrog%C3%A8ne-energie-h2e http://www.fch-ju.eu/ http://horizon2020projects.com/sc-transport-interviews/storing-energy-in-horizon-2020/ http://horizon2020projects.com/sc-transport-interviews/powering-the-future/ http://cordis.europa.eu/fp7/ideas http://ec.europa.eu/programmes/horizon2020/en/ http://ec.europa.eu/transport/themes/research/horizon2020_en.htm http://www.agnimotors.com/site/ http://www.engadget.com/2012/11/13/mclaren-to-supply-ev-groundwork-for-formula-e-cars/ http://www.telegraph.co.uk/finance/The-electric-cars-of-the-future.html http://www.greencardesign.com/site/galleries/racing-drayson-b1269ev

Intelligent Battery Support System THE BLUE BIRDS OF HAPPINESS

The Ecostar DC50 incorporates the patent Bluebird™ instant energy transfer system - allowing EV refueling for road cars in around 60 seconds. The blue bird legend continues.

HISTORY - A GOOD YEAR - The year 2014 was significant as the 50th anniversary of Donald Campbell's (DCs) extraordinary double, achieving the land and water speed record in the same year, thanks to the engineering genius of Ken Norris and his brother Lewis. Nobody had ever done that before and nobody is likely to do it again. The directors of BMS thought that they might do something as a tribute to the occasion and as recognition of the achievements of these astonishing Englishmen, and what better than a sports car, where Donald's designers had a keen eye for style, but never had the pleasure of seeing a blue bird emblem on a road car. These gentlemen were though working on a production speed boat with Leo Villa - so maybe a car would have been next on their shopping list, in the tradition of Reid Railton and Ken Norris, forever looking to improve the concept.

ECOSTAR LINKS A-Z

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This

website is Copyright © 2020 Bluebird Marine Systems Limited.

The names Bluebird™,

Ecostar DC50™,

and the blue bird in flight

|