|

AMPHIBIOUS LAUNCH - AMPHIMAX - CAB - CHASSIS - DIESELS - FLOATATION - HYDRAULICS - LAUNCH SITE - MODEL 1/20 - TIMETABLE - TRACKS - TRAILER - THRUSTERS - WHEELS

|

|

|

HYDRAULIC CIRCUIT - Where bow thruster propellers are underwater a hydraulic motor is a practical means of power transmission. Higher overall efficiency is achieved with piston-type hydraulic motors. These motors are said to be 10 - 18% more efficient than the vane or gear motors used in most thrusters. As a result, overall efficiency (in terms of thrust per input horsepower) could be 20 to 33% greater than competing products.

Handling a ship in currents, wind and tide is always a tricky affair. All these three factors can laterally shift the vessel from its course. A ship’s pilot has to keep an eye to these effects and constantly take remedial measures for safe

navigation of the ship.

We

want to be able to steer AmphiMax onto our beach at right angle (ninety degrees)

to the shoreline. Where we specify bow thrusters for steerage, this is because

they have the qualities that we need in a convenient package that is designed to

provide high thrust that is useful to us to ensure that our tracks achieve bite

on the shingle positively.

RIM MOTORS - This design of thruster has technical benefits that are not yet fully exploited for driving vessels.

WHAT IS A BOW THRUSTER?

A bow thruster or stern thruster is a transversal propulsion device built into, or mounted to, either the bow or stern, of a ship or boat, to make it more maneuverable. Bow thrusters make docking easier, since they allow the captain to turn the vessel to port or starboard side, without using the main propulsion mechanism which requires some forward motion for turning; indeed, the effectiveness of a thruster is curtailed by any forward motion due to the Coandă effect. A stern thruster is of the same principle, fitted at the stern. Large ships might have multiple bow thrusters and stern thrusters.

BLUE

ROBOTICS - The T200 Thruster is one of the world’s most popular underwater thruster for ROVs, AUVs, surface vessels, and more! Its patented flooded motor design makes it powerful, efficient, compact, and affordable. The T200 is in use on thousands of marine robotic vehicles around the world.

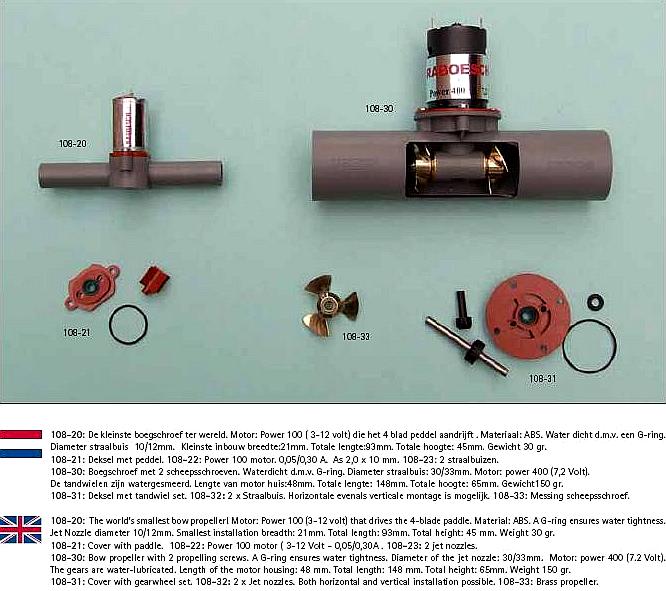

RABOESCH - Vane and contra-rotating propeller tunnel based bow thrusters for ship models.

TUNNEL THRUSTERS

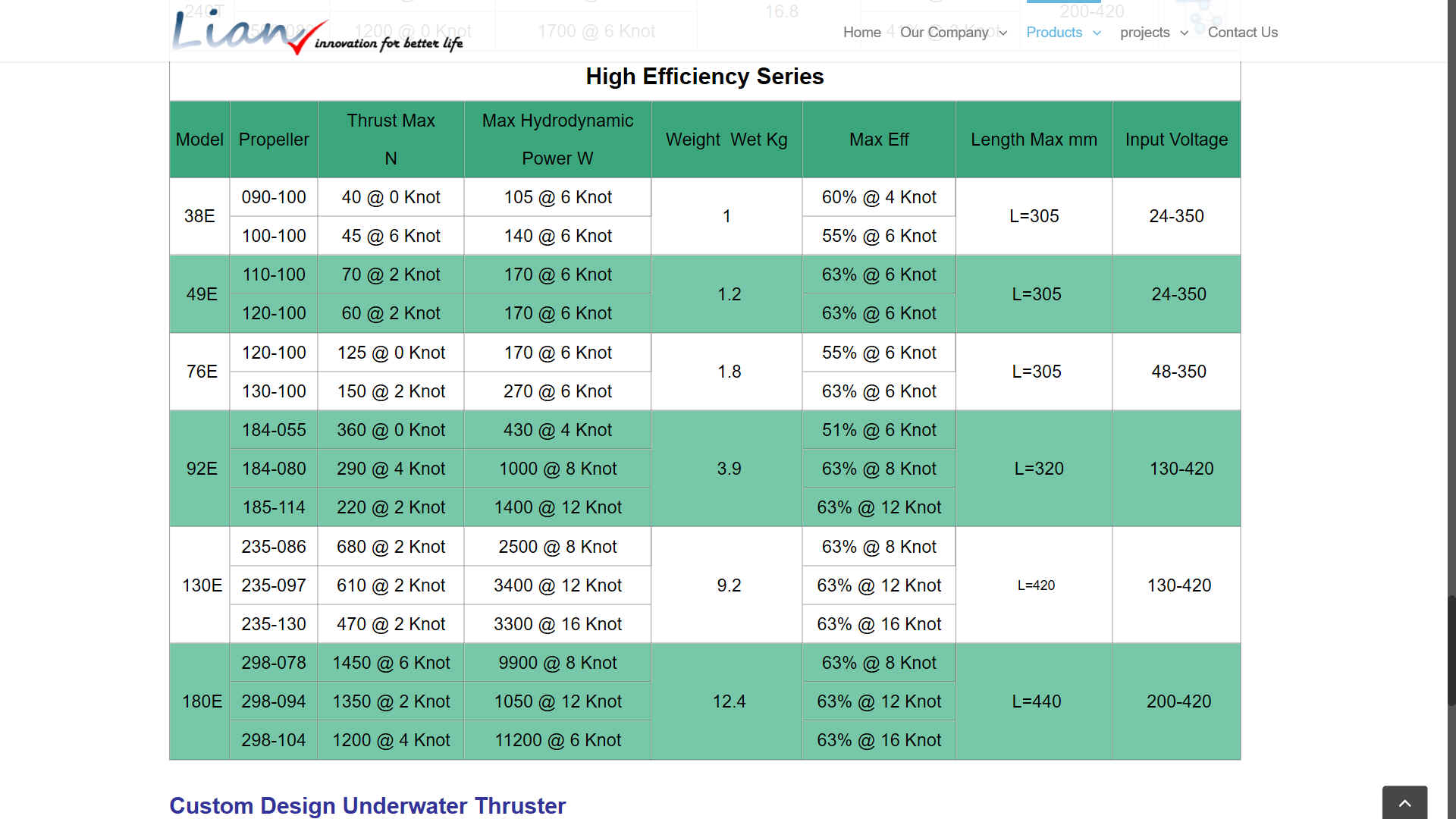

CUSTOM BUILD - High efficiency or high thrust depends on your choice of motor, impeller and voltage. Lian quotes efficiencies of 63% at certain speeds for certain motor/impeller combinations. Not bad!

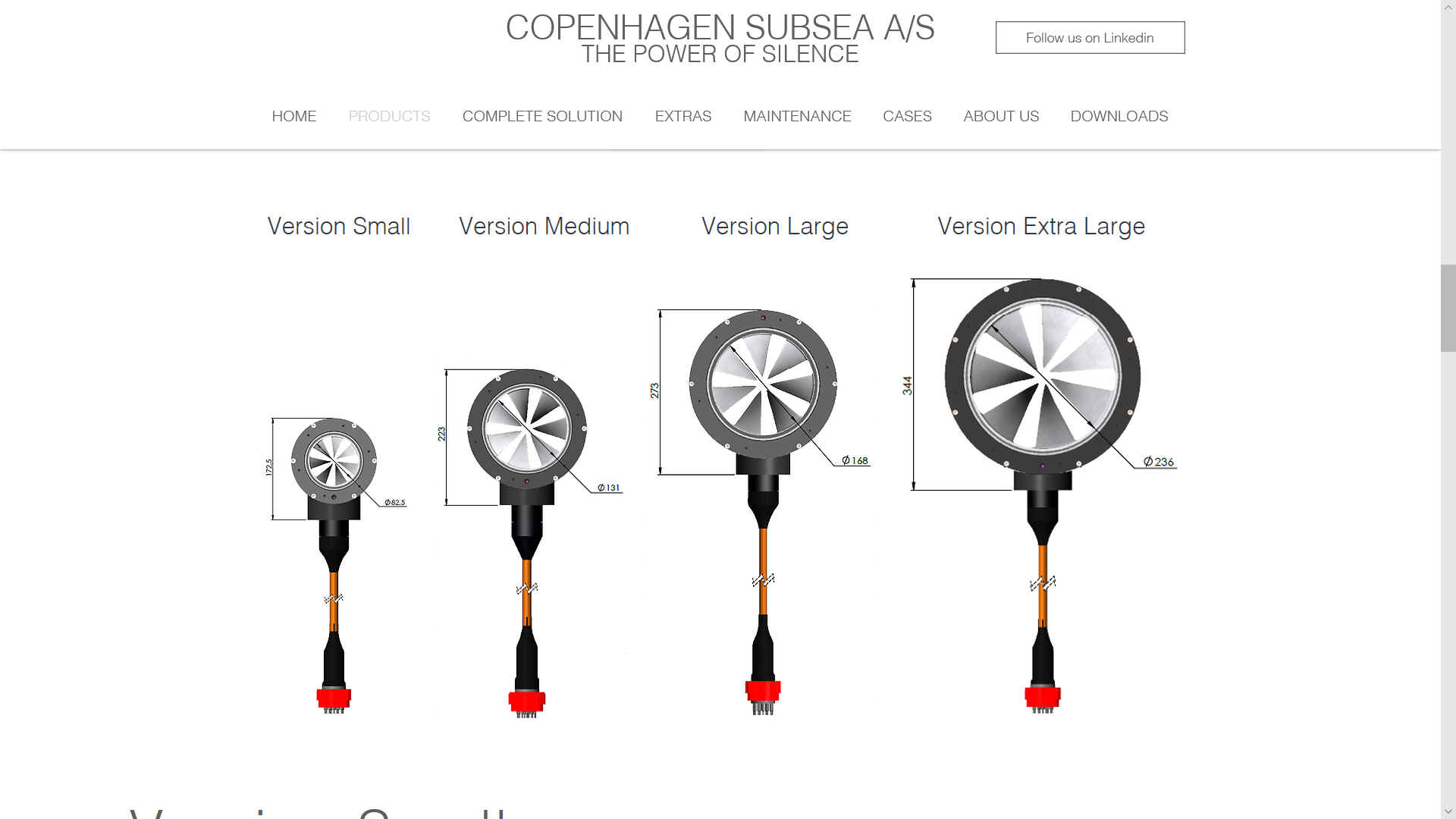

EXTERNAL BOW THRUSTERS

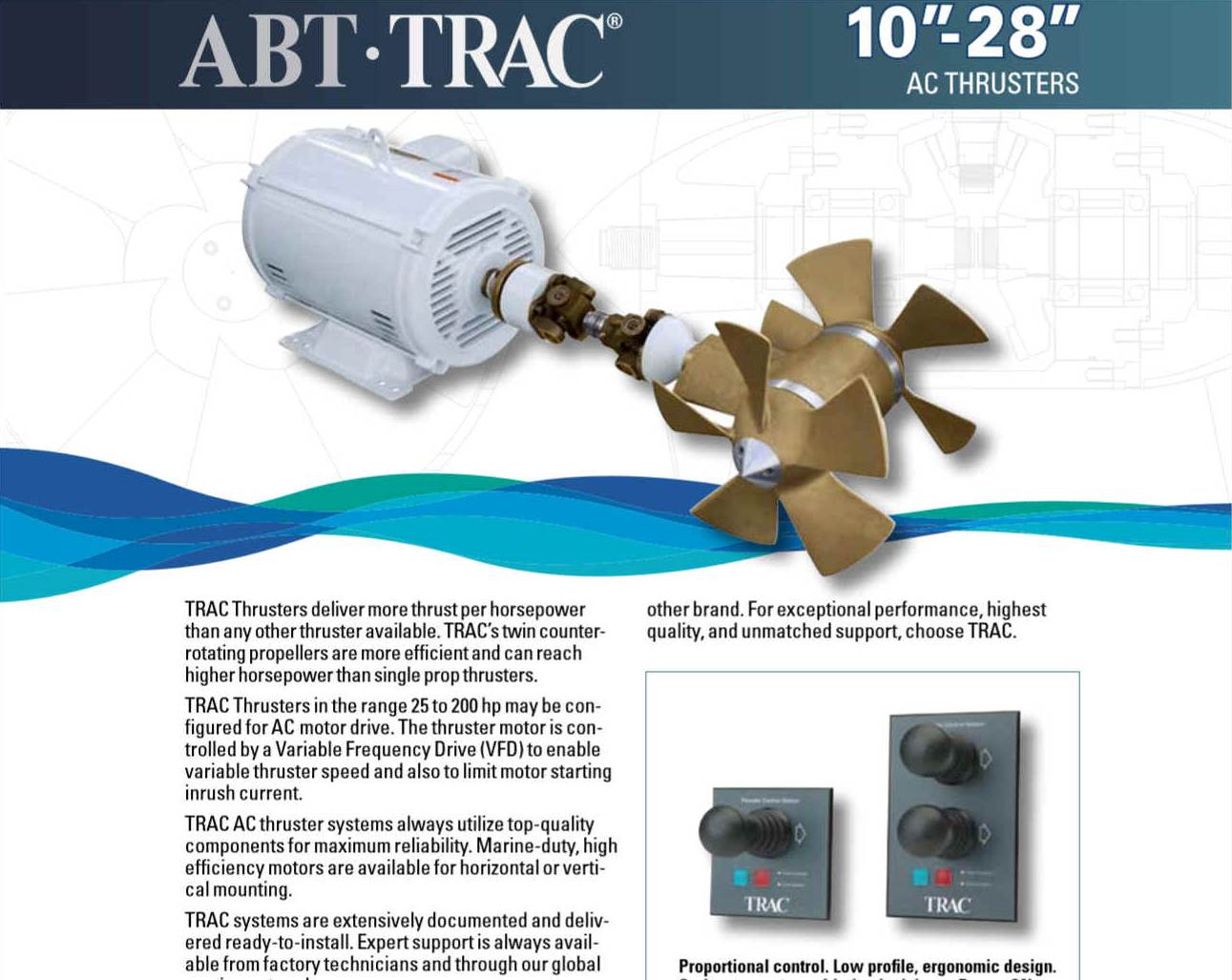

AC-DC - ABT•TRAC Hydraulic Thrusters claim to deliver more thrust per horsepower than any other thruster available. ABT•TRAC's twin counter-rotating propellers are more efficient and can reach higher horsepower than single prop hydraulic thrusters. ABT•TRAC hydraulic thrusters are fitted with high efficiency piston motors. They are available in seven sizes, from 8 inches up to 28 inches. The 8 through 12-inch thrusters are available in a DC version and all ABT•TRAC thrusters are available in AC versions. Thruster control is available in single or proportional speed. Proportional thruster control enables precise maneuvering control.

WATERJET BOW THRUSTERS

DOCKING - This is the Blue Star "Naxos" turning in port to dock using her bow thrusters.

BM SYSTEMS

In ....... to be completed ......

CONTRA ROTATING IMPELLERS - Traditional single propeller systems generate thrust by accelerating water in the axis of the propeller shaft. However, the water discharged by the propeller also rotates. This is due, in part, to the friction between the surface of the propeller and the water. This rotational component does not produce thrust, but it does consume energy. By turning the propellers in opposite directions, the efficiency of the a thruster becomes 10 to 15% greater than that of single propeller systems. This has to be offset by frictional losses in the bearings and gears, but overall there is a gain with additional cost and complexity. Another method used to increase the efficiency of water (jet) pumps is a fixed stator. Torpedoes that have to travel at high speed use contra-rotating propellers for this reason.

LINKS & REFERENCE

http://voith.com/corp-en/industry-solutions/marine-technology.html http://www.smartmotor.no/products/rov_auv https://www.brunvoll.no/products/manoeuvring-systems https://silentdynamics.de/ http://www.tsltechnology.com/marine/thrusters.htm https://bluerobotics.com/ http://www.marineinsight.com/marine-navigation/how-bow-thruster-is-used-for-maneuvering-a-ship/ http://www.lewmar.com/thrusters http://loganclutch.com/ https://sideshift.com/ http://www.mitgroup.co.uk/bcs http://www.thrusters.com/ http://www.thrusters.com/products/thrusters_hydraulic.shtm http://www.hiseamarine.com/bow-thruster-1087.html http://www.max-power.com/ http://www.nauticexpo.com/boat-manufacturer/bow-thruster-2706.html

AMPHIBIOUS LAUNCH - AMPHIMAX - CAB - CHASSIS - DIESELS - FLOATATION - HYDRAULICS - LAUNCH SITE - MODEL 1/20 - TIMETABLE - TRACKS - TRAILER - THRUSTERS - WHEELS

|

|

|

This page is Copyright © 2020 Bluebird Marine Systems Ltd. The names AmphiMax™, Bluebird™, Bluefish™, RiverVax™, SeaNet™, SeaVax™ and the blue bird & fish in flight logos are trademarks. All other trademarks are hereby acknowledged.

|