|

THE PROPELLER

PLEASE USE OUR A TO Z INDEX TO NAVIGATE THIS SITE |

||

|

What seems ordinary today was quite revolutionary 200 years ago. Thanks to the dedication and ingenuity of great thinkers on water propulsion, we have ships that run at around 45-60% efficiency. That can be a lot higher is we continue to develop the concept - and we need to in order to avert a climate meltdown, aiming for 70-80%.

Paddle steamers are much like rotary oars, being drag devices. They are good for shallow river boats even today, where they are less likely to snag on weeds than unguarded propellers. The development of paddle wheels got engineers thinking about machinery as propulsion over sails - as being normal - so a great leap forward, in relieving able bodied seamen from going aloft to furl sails and the like.

The development of the propeller overtook the efficiency of paddles due to the efforts of a number of inventors. This is typical of the development of most technology, where it is the collective human brain that moves us along on the shoulders of intellectual giants.

A ship’s screw acts on water that is moving around the hull. As a ship moves forward she disturbs the laminar flow of the water with turbulence at the aft of the hull, that materially affects the screw’s performance because of the way the water approaches the screw. This was not appreciated with paddle wheels set on either side of a hull.

In addition, where early propellers were partly drag devices, the science of airfoils, or hydrofoils was not appreciated until wing experiments on aircraft, by (for example) the Wright Brothers in the late 1800s. Before that propeller blades included foil properties by accident.

JOHN ERICSSON improved ship design with screw-propellers. However, the Admiralty disapproved of the invention as being disruptive. As a result, in 1839, Ericsson took his talent to New York where Captain Robert Stockton obtained funding for a 700-ton sloop called the USS Princeton. Approaching completion of this ship Stockton began working to force Ericsson from the project having avoided letting outsiders know that Ericsson was the inventor. Such struggles are commonplace for innovators whose work and reputation suffers, but is nevertheless noteworthy and Stockton then did all he could to prevent Ericsson from being paid for his work because he knew that well funded Ericsson would triumph and that that success would then expose his misdirection.

Despite

giving Ericsson a cold shoulder, the British Admiralty knew that screw propulsion had obvious advantages for warships.

Paddle wheels were exposed to enemy fire in combat, whereas a propeller and its machinery were tucked away

below deck. The space taken up by paddlewheels restricted the number of guns a warship could carry, thus reducing its broadside.

Stubbornly the Admiralty refused to budge until Ericsson was otherwise

engaged. Then in 1840 the world's first propeller-driven steamship, SS Archimedes, successfully completed a series of trials against fast

paddle-wheelers. That demonstration got the Navy's attention and they

wanted more data. Finally, in 1845 the British Navy decided to compare the two systems

conclusively. For the comparison, two near equal ships were selected. In the paddlewheel corner was the champion, HMS Alecto, weighing in at 880 tons, with a 200 hp steam engine. The challenger was the propeller driven HMS Rattler, also weighing in

880 tons and also with a 200 hp steam engine.

The screw propeller was introduced in the latter half of the 18th century. David Bushnell's invention of the submarine (Turtle) in 1775 used hand-powered screws for vertical and horizontal propulsion. Josef Ressel designed and patented a screw propeller in 1827. Francis Pettit Smith tested a similar one in 1836. In 1839, John Ericsson introduced the screw propeller design onto a ship which then sailed over the Atlantic Ocean in 40 days. Mixed paddle and propeller designs were still being used at this time (vide the 1858 SS Great Eastern).

In 1848 the British Admiralty held a tug of war contest between a propeller driven ship, Rattler, and a paddle wheel ship, Alecto. Rattler won, towing Alecto astern at 2.8 knots (5 km/h), but it was not until the early 20th century paddle propelled vessels were entirely superseded. The screw propeller replaced the paddles owing to its greater efficiency, compactness, less complex power transmission system, and reduced susceptibility to damage (especially in battle).

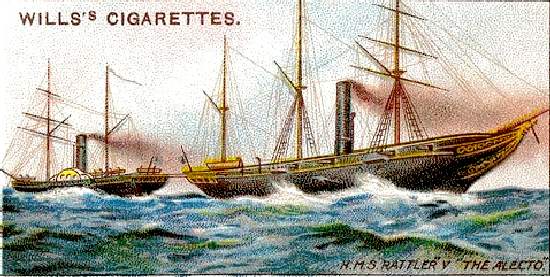

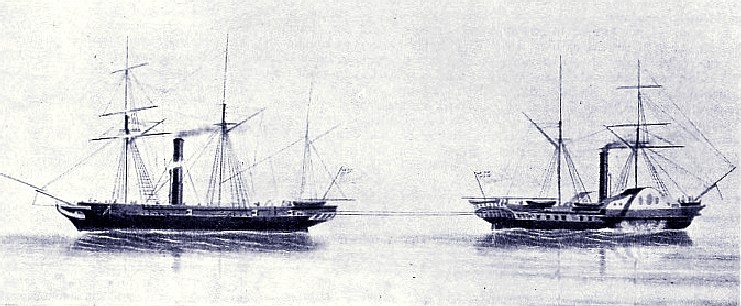

TUG OF WAR - The Rattler and Alecto performance experiment of 1848, where the propeller ship pulled the paddle steamer backwards at 2.8 knots. Still the British stick in the muds turned a blind eye, most likely so as not to upset existing contracts and special arrangements pertaining thereto.

PROPELLER DEVELOPMENT HISTORY

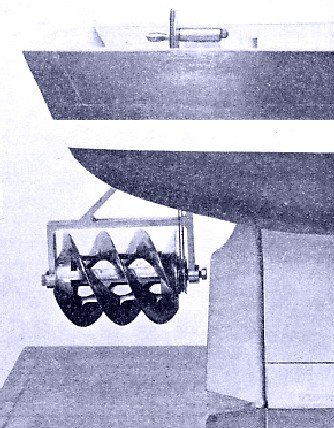

1794 - A triple-threaded screw was patented by William Lyttleton. This propeller was designed for mounting in a frame attached to the ship’s hull. It was to have been driven by manually-operated winches through a system of ropes and pulleys. A boat fitted with this device was tried in Greenland Dock, London, but a speed of only two miles an hour was attained.

A triple threaded screw was patented by William Lyttleton in 1794. It was mounted in a frame that could be attached to the bow, stern or sides of a ship a bit like an outboard engine. The screw was designed to be operated manually by ropes from winches on the vessel’s deck.

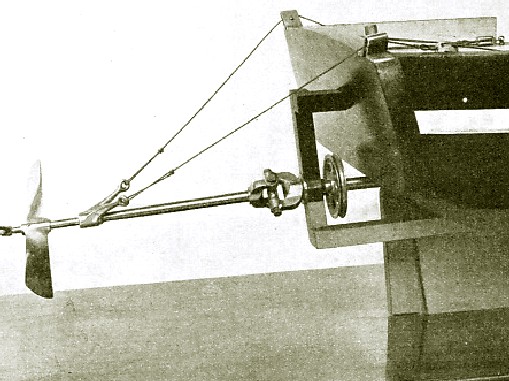

1800 - A similar device was invented by Edward Shorter. His design consisted of a two-bladed propeller on an inclined shaft supported by a buoy at the stern of the vessel. The inclined shaft carrying the propeller was driven through a universal joint by a second shaft on the ship above the water-line. The transport Doncaster was fitted with Shorter’s propeller. With eight men at the capstan to provide the motive power, she attained a speed of one and a half miles an hour during a calm in Gibraltar Bay and later at Malta.

PATENTED IN 1800, Edward Shorter’s screw propeller was described as a “ perpetual sculling machine”. The screw was submerged in the ship’s wake and was prevented from sinking by a buoy attached to the shaft at the far end. The device was manually operated and tested at a transport event in Doncaster, in 1802. The best speed reached was under two miles an hour.

1804

- Edward Shorter also suggested that his propeller might be driven by a steam-engine, but the first attempt at this method of ship propulsion is credited to an American, Colonel John Stevens, in 1804. Colonel Stevens’ boat was a small twin-screw steam launch. She made a number of successful trial runs in New York Harbour, but these experiments were not crowned with any commercial success.

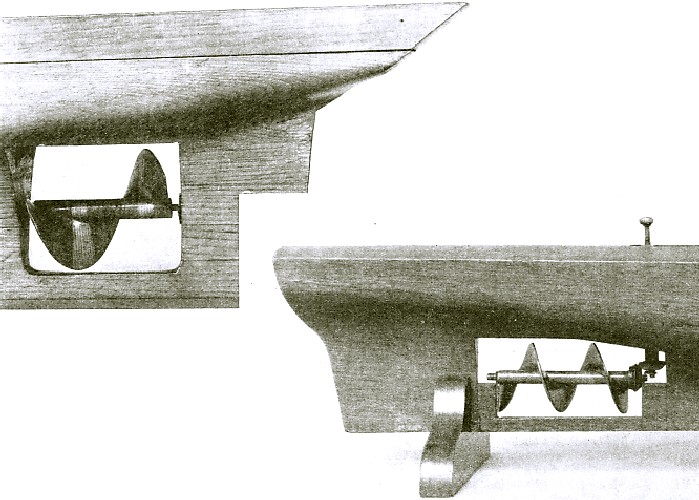

The original design of the screw propeller patented by Sir Francis Smith is seen on the right. In 1836, the launch F. P. Smith, fitted with this screw, was given a trial on the Paddington Canal, London. At this event half of the screw broke off, whereupon the vessel went considerably faster. The inventor then devised the screw with a single turn, as shown on the left above - in effect, a two-bladed propeller.

1836 - Francis Smith, a farmer at Hendon (Middlesex), patented a single-threaded screw propeller with two complete twists resembling part of a large cork-screw. This revolved in a recess at the stern of the ship. Smith conducted his early screw experiments with a clockwork-driven model on a pond.

Francis Smith used models for his early experiments and Ericsson adopted similar measures. He experimented with a model ship in a circular tank, from the centre of which projected a tubular arm. The model was fitted with a propeller driven by a small steam engine. Steam was supplied to the engine through the rotating tubular arm.

So successful was

Smith's little boat that a launch of 6 tons burden, named after the inventor, was built at Wapping. The screw, mounted on a horizontal shaft, was driven by bevel gearing through a vertical shaft reaching above the waterline. The motive power was a steam-engine with a cylinder of 6-in bore and 15-in stroke.

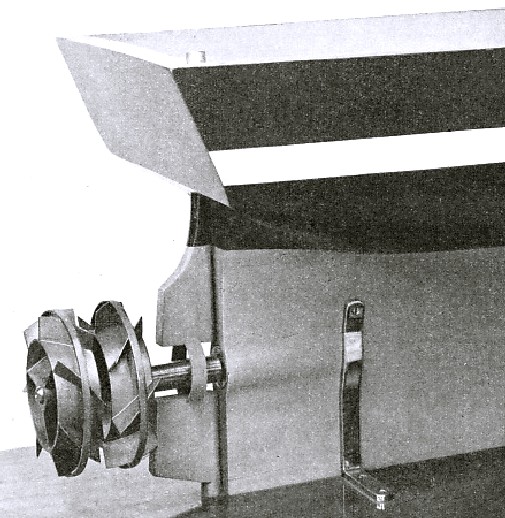

JOHN ERICSSON - The famous engineer from Sweden retired from the Swedish army, settled in England and worked independently of Smith. In 1836 he also patented a screw propeller consisting of two drums on a shaft. Either drum had a series of helical blades round the periphery, and the blades on one drum were inclined in the direction opposite to those on the other drum. An interesting feature of Ericsson’s propeller was the arrangement of the two drums. These were mounted on a common axis, but they revolved in opposite directions. The after drum revolved at a faster speed because it acted in water that had already been set in motion by the forward drum. This arrangement is know as contra-rotating propellers.

The reversed direction of the after drum was intended to counteract losses caused by the rotary motion of the water behind the leading drum. The arrangement of duplex screws was not adhered to in marine practice, because experience indicated that the complication involved did not improve performance. Ericsson himself often made use of a single screw. A survival of twin screws revolving in opposite directions on one shaft is found in modern torpedos. The arrangement is there used to counteract the “torque” or force that would endeavour to turn the torpedo over against the direction of a single propeller’s rotation.

CONTRA ROTATION - A version of this is now used in an improved form for the modern torpedo. This form of screw was the invention of Captain John Ericsson, the famous Swedish engineer. The forward drum, fitted with helical blades, revolved in one direction and the after drum was turned in the opposite direction at a faster speed. Not bad for 1836.

1837 - In this year the screw propeller was successfully applied to ships, and the honour of contributing this important development in marine engineering is shared by Francis Pettit Smith and by Captain John Ericsson, who worked independently.

The first practical test of Ericsson’s propeller was carried out on the Thames. A 45 ft boat, the Francis B. Oyden, was fitted for screw propulsion. She towed the Admiralty barge, with some of the Lords of the Admiralty on board, from Somerset House to Blackwall and back at an average speed of ten knots.

1838 - After other experiments had been carried out, a United States naval officer, Captain R. F. Stockton, arranged for the construction of a vessel 70 feet long by 10 feet beam, with engines driving directly to the propeller shaft. This ship, the Robert F. Stockton, was built at Birkenhead by Laird Bros, in 1838, and attained a speed of thirteen knots with the tide. She crossed the Atlantic under canvas early in 1839 and saw many years service as a tug in New York harbour under the name New Jersey. Ericsson left for the United States later in 1839. There his invention was used in a number of American river steamers and in the U.S. warship Princeton, built in 1842.

1839

- After these experiment where his screw drive broke and increased

performance, Smith amended his patent specification and his screw was described as consisting of a single turn or alternatively a double thread with two half-turns. In this manner was evolved the two-bladed screw propeller.

1843 - The Earl of Dundonald patented a propeller with the blades inclined aft to prevent any outward flow of water. Other inventors provided concentric ridges on the blades to achieve the same object, and some screws were sickle-shaped.

1845 - The superiority of the screw propeller over the paddle wheel for the propulsion of ocean-going ships was generally accepted by the end of 1845. In April of that year

the famous “duel” between H.M.S. Rattler and H.M.S. Alecto took place. The vessels were similar in size and of equal nominal horse-power, but the screw-driven Rattler, when lashed stern to stern with the paddle-sloop Alecto, was able to tow her rival astern at a speed of nearly three knots.

1860-66 - A sickle-shaped propeller was patented by Hermann Hirsch.

1870 - A number of ships were fitted with four-bladed screws of this type. Originally the vessels had been equipped with Griffiths screws, and it is said that after the change their speeds were increased by about one knot.

MODERN BRONZE - Today large propellers are cast in bronze, while smaller versions use more exotic alloys. A gearbox to achieve contra-rotation, one shaft inside the other.

AIRSCREWS

- Contra-rotating props are the (almost) exclusive realm of powerful engines with very high disk loading. The most recent designs prefer to use more blades and avoid a heavy gearbox, but the efficiency of such props is poorer than that of propellers with lower disk loading and fewer blades. In a way, the efficiency of the eight-bladed propellers

of the Hamilton-Sundstrand NP2000

above is similar to that of four two-bladed propellers in sequence, but it is much easier to build with all blades and their pitch mechanism in one hub.

SHORT HISTORY OF JOHN ERICSSON

In 1826 Ericsson went to London, where he worked mainly on engines and on locomotives and screw propulsion for boats, receiving 14 patents. English railroad builders kept him profitably at work.

ERICSSON'S

US NAVY RESENTMENT

As a result, Ericsson moved to New York in 1839. Stockton's plan was for Ericsson to oversee the development of a new class of frigate with Stockton using his considerable political connections to

lubricate the financial wheels. Finally, after the succession to the Presidency by John Tyler, funds were allocated for a new design. Unfortunately they only received funding for a 700-ton sloop instead of a frigate. The sloop eventually became the USS Princeton, named after Stockton's hometown.

Stockton carefully avoided letting outsiders know that Ericsson was the primary

inventor. Stockton attempted to claim as much credit for himself as possible, even designing a second 12-inch gun to be mounted on the Princeton. Unfortunately, not understanding the design of the first gun (originally named "The Orator", renamed by Stockton to "The Oregon"), the second gun was fatally flawed.

Unfortunately, during a firing demonstration of Stockton's gun the breech broke, killing the US Secretary of State Abel P. Upshur and the Secretary of the Navy Thomas Gilmer, as well as six others. Stockton attempted to deflect blame onto Ericsson with moderate success despite the fact that Ericsson's gun was sound and it was Stockton's gun that had failed. Stockton also refused to pay Ericsson and, using his political connections, Stockton managed to block the Navy from paying him.

These actions led to Ericsson's deep resentment toward the US Navy. A warning to any inventor, not to trust navies, or work for them. You are likely to end up working for nothing. Always get payments up front from those looking to benefit from your efforts. Military organisations have absolute power to discredit and ruin anyone who gets in their way.

In the end, Ericsson's ironclad warships earned him a special place in Civil War history, despite the unfortunate episode above. A lesson perhaps to naval officials and everyone else to play with a straight bat.

SOLUTIONS

- The chronometer was vital to the ability to create charts and safely navigate the world. The first chronometers were invented by a carpenter's son:

John

Harrison.

This gimbaled Marine Chronometer seen above was one on H.M.S. Beagle during its second voyage (1831-1836) with Charles Darwin onboard. It sailed to the coast of South America, across the South Pacific towards the Galapagos Islands, New Zealand and Australia, in order to help establish a chain of reliable navigational co-ordinates around the globe.

LINKS & REFERENCE

https://www.shippingwondersoftheworld.com/screw_propeller.html https://www.encyclopedia.com/people/science-and-technology/technology-biographies/john-ericsson https://civilwar.wikia.org/wiki/John_Ericsson

|

||

|

This website is Copyright © 2020 Bluebird Marine Systems Limited. The name Bluebird™ is a registered trademarks.

|

||