|

FCH2020 LIQUID HYDROGEN FOR EVs

PLEASE USE OUR A TO Z INDEX TO NAVIGATE THIS SITE OR SEE HOME

|

|

THE SLOW LANE - We all live fast lifestyles. Waiting 30 minutes for rapid charging, even with smart technology, potentially strains the grid, and also damages batteries. And super speed charging strains the grid unacceptably.

There are faster ways of refuelling an electric vehicle with hydrogen or battery cartridges, in just a couple of minutes using off-peak stored energy. Battery swapping could be the solution, provided that it is properly thought out and developed with collaboration from all concerned, interchangeably with hydrogen cartridge swapping - looking to the future.

H2020-JTI-FCH-2020-1

: FCH-01-3-2020

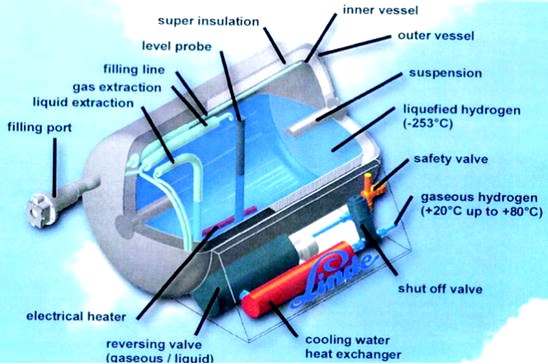

Liquid Hydrogen on-board storage tanks

The range limitation is less critical for fleet trucks with short routes: 350 bar H2 storage seems to be sufficient for municipal vehicles, buses and even parcel delivery trucks. For trucking applications with larger payload and less dense HRS network, for instance regional and long haul, other solutions need to be investigated.

Pressures

of 500 to 700 bar indeed offer more volumetric capacity (more than 20 to

45% over 350 bar) but these solutions are costly and bring in hurdles on

the infrastructure where large capacities need to be dispensed rapidly,

while controlling the inlet temperature and allowing high station demand

(“back-to-back”).

No industrial actors or consortia have started to develop consistently such technology in the world.

Actors of the EU

industry are currently well positioned and by pursuing this activity, have

the potential to become world leaders.

Even though on-board LH2 storage has been disregarded for light-duty

vehicles, its relevance for applications that

require larger capacities (40 to more than 100kg H2) and that experience

much more utilization (more than 100,000 km/year) deserve to be carefully

evaluated.

Whereas, no on-board LH2 storage for transportation vehicles exists today. The on-board environment has very unique challenges for LH2: insulation optimization vs. gravimetric, functional, mechanical and safety requirements, fluid regulations for various modes (acceleration, parking refuelling etc.), compliance with stringent regulations and end-user interface.

TECHNOLOGICAL ADAGE - It is the part of a wise man to keep himself today for tomorrow, and not to venture all his eggs in one basket. SMARTNET allows for change in technology. You don't have to bet on batteries or fuel cells. Include both in a diverse asset portfolio - and watch you egg hatch into a solution.

UNIVERSAL BATTERY CARTRIDGE FORMAT PROPOSAL - This cartridge format provides 0.24 of a meter cubic capacity. All of these formats can be used in multiples to provide up to 1.92 of a cubic meter capacity. This is one of a number of sizes that we will be evaluating as part of a study we hope to obtain funding for in relation to electric vehicle chassis design. The proposed cartridge is compatible with the SMARTNET services stations concept. The cartridge may be designed to accommodate cars and trucks. The 'Universal' format cartridge is intended to be compatible with hydrogen storage or battery storage. Cleaner Ocean Foundation is looking to either form a consortium to further the concept, or to join an existing consortium to include commonality for alternative proposals.

SCOPE:

This will include an investigation from the end-user perspective, by simulating real-life utilization (H2 extraction, driving, parking and refuelling) and making sure that the state-of-charge, the actual boil-off and the refuelling are compatible with the expectations.

A few configurations will be used as benchmark: rail mounting, behind cab, and within frame. The overall shape of the storage system is important, and advanced storage solutions to optimize the energy density (through e.g. a single vacuum jacket with multiple cylinders) should be investigated.

The mechanical design should meet all requirements typical of the trucking industry in terms of durability, exposure to harsh environments, vibrations, accelerations, safeties.

Pressure in the LH2 storage tank should be compatible with the pressure at which the fuel cell typically operates. Alternatively, mitigation strategies should be proposed.

EV REFUELLING COMPARISON - Where charging up a battery-powered car can take anything from half an hour to a whole night, you can refuel a hydrogen car in just five minutes using flexible hoses. But, you can also refuel a battery car in less time using cartridge exchange. Meaning that hydrogen loses out, if we take into account energy conversion losses. For this reason hydrogen is unlikely to achieve the same level of market penetration, without a means to work alongside battery vehicles, such that the choice for the buying public is not such a risk, as if putting all your eggs in one basket. ....

EUROPEAN AUTO MANUFACTURERS INCLUDE:

- Audi - BMW - Citroen - Fiat - Ford - Lotus - Mercedes - Peugeot - Renault - Seat - Smart

MAKES OF ELECTRIC TRUCKS

- DAF - MAN - Renault - Volvo

MAKES OF ELECTRIC BUSES & COACHES

- BDY

CANCER

- Many of the compounds released during burning of hydrocarbons are associated with

cancer and often cause short irritation of the respiratory tract and eyes.

SOME OF THE BIGGEST ELECTRICITY POWER COMPANIES A - Z

Duke Energy Corporation, DUK, N. Carolina, USA Dominion Energy Inc., Richmond, Virginia Exelon Corporation EXC, Chicago, USA KEPCO Korean Electric Power Corporation National Electric Grid & Central Electricity Authority (India) National Energy Board (Canada) National Grid plc (formerly Central Electricity Generating Board UK) Next

Era Energy Inc. Florida, USA Southern Company, Atlanta, Alabama, Georgia, Mississippi, USA State Grid Corporation of China TEPCO Tokyo Electric Power Company

LINKS & REFERENCE

https://www.theengineer.co.uk/hydrogen-heavy-duty-trucks-lorries/ https://www.innovationplace.eu/fund/h2020-fch-01-3-2020-liquid-hydrogen-on-board-storage-tanks-/2400 https://www.enterprise-europe.co.uk/opportunities/RDUK20200320001

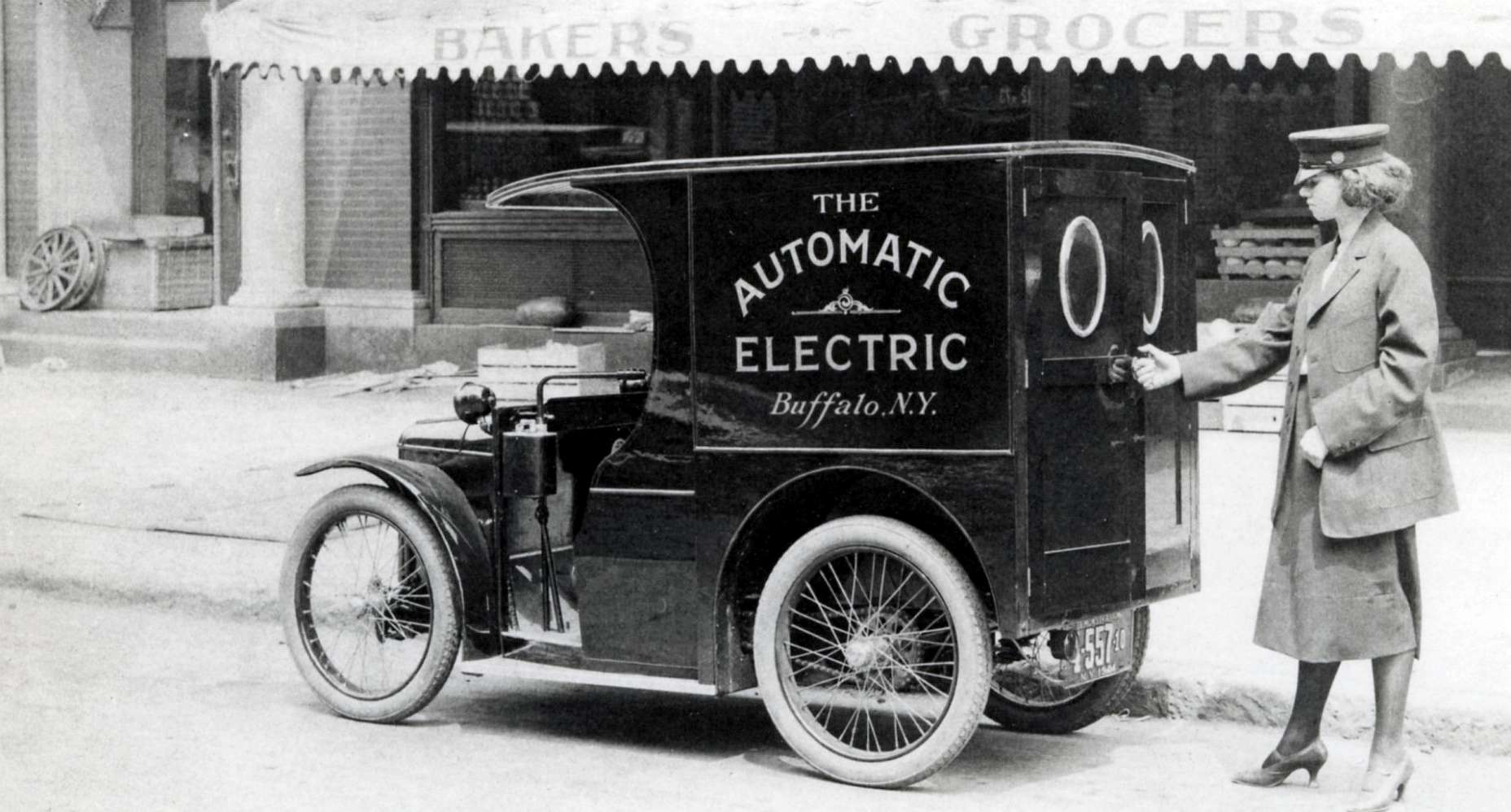

1921 - A chain driven electrically powered van in Buffalo, N.Y. It was called an automatic, because there was no gearbox. They were easier to drive and did not need starter handles that most women could not manage, hence this picture advertising a lady operator in high heels. Professor Ferdinand Porsche invented battery cartridge exchange in the early 1900s. This was for his electric cars. He also even invented the hybrid, where a petrol generator charged the onboard batteries that powered electric hub motors.

|

|

This

website is Copyright © 2020 Bluebird

Energy Systems. The

names Bluebird,™ and the blue bird in flight

|