|

DINOBOT - GIANT ROBOT ANT - LEGS

ANTICS - ARDUINO - ARMOUR - ARTWORK - BIOLOGY - BLACK BOX - COMPUTERS - ELECTRONICS - ENERGY - FRAME FORMICARIUM - HEAD - JAWS - JIMMY WATSON - KITS - LEGS - MECHANICS - MOTORS - MOVIE - PHOTOGRAPHY - RASPBERRY Pi R/C DRONE - SENTRY SOFTWARE - SOUND PROOFING - SPACE ROVERS - SPEED - SUSPENSION - TAIL - UKRAINE DRONES - WEAPONS - WARGAMING

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EYE SEE - Ants have compound eyes that see in colour, according to recent research.

DINO GIANT ROBOT ANT - DINOBOT LEGS

Insects have six legs that are matched in 3 pairs. The lengths of the thighs or femur are different, getting longer as we go from head to tail. Whereas the shins or tibia are relatively similar in length. The ant can pivot its body on the middle and aft legs to be able to swing the abdomen and sting forward. When walking or running the body is virtually horizontal with the tail raised for more ground clearance.

Our development robot is designed for walking and running, not for other positions - and that is because we have to be practical and cost conscious. A kit with a hydraulic movement will cost several times that of the variable track system that is relatively affordable. Even then we need two motors and two speed controllers.

FABRICATION

We will be making the first set of legs in 16 gauge aluminium tubing. This may be far more sturdy than is absolutely necessary - and for sure a heavier gauge that any tubing we might use for a high speed version, say for a land speed record attempt - but when treading in unknown territory, it is better to start where you know you are safe - and then work backwards to fine sections.

Using a relatively generous wall section will make joints and connections more tolerant - and we can overload the chassis a little and learn - though we may use strain gauges to see what is happening when the going gets tough. See more on that below.

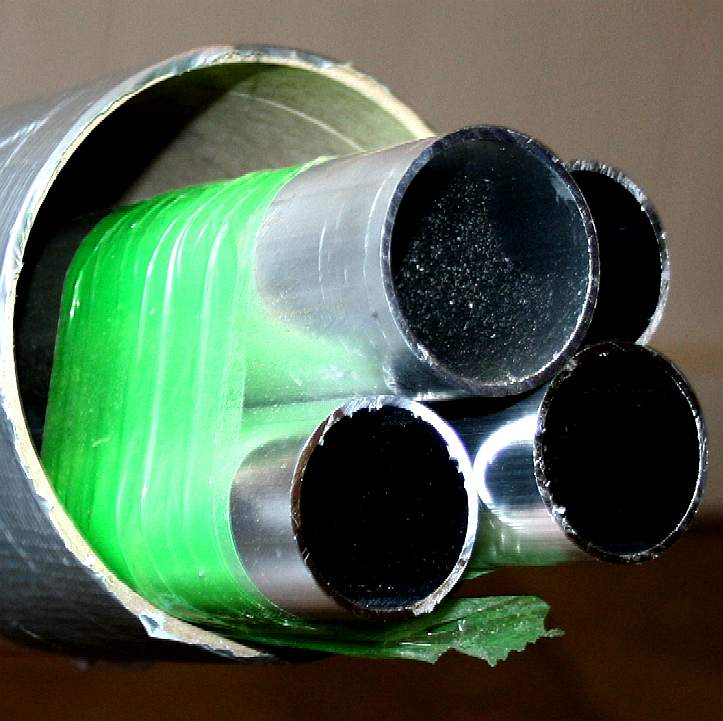

We chose a wide selection of diameters to be able to experiment for best results, from 3/4 inch (19mm) to 1 5/8 inch (41mm) with 1 inch (25.4mm) and 1 3/8 (35mm) inch steps.

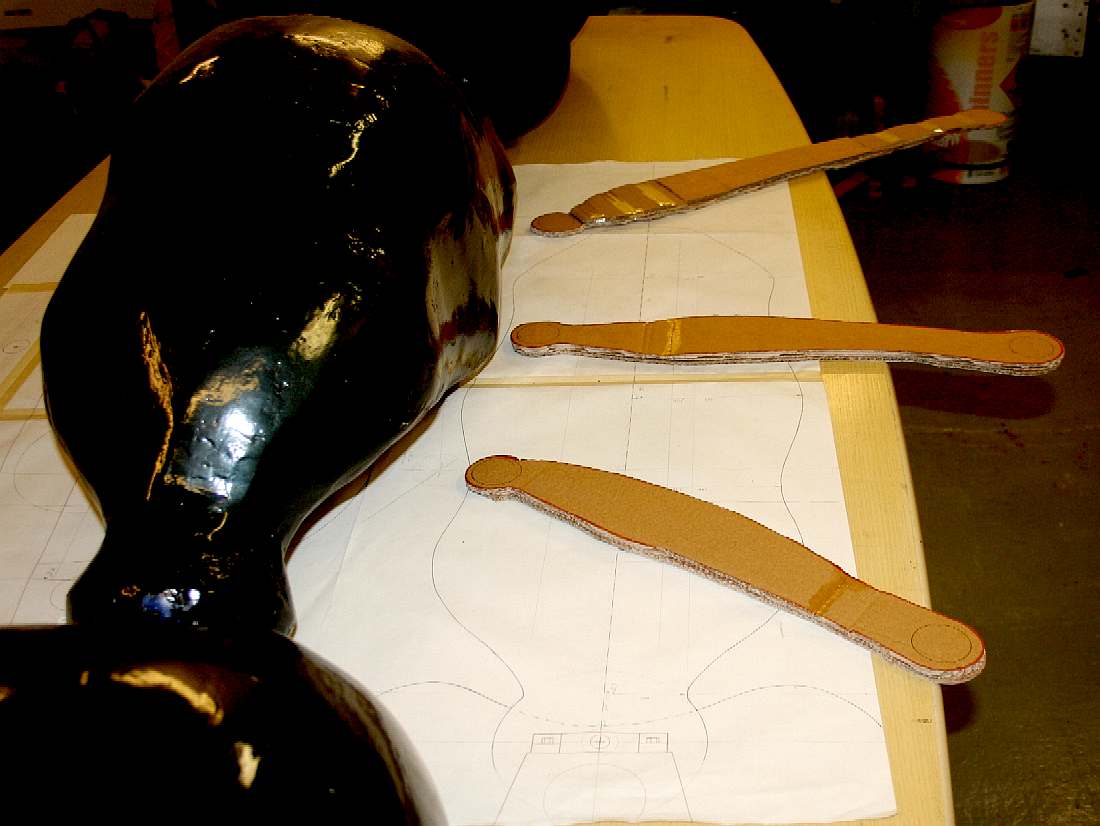

LEG MASS v COST - Aluminium legs in 28.5mm tubing is likely to be around £35 + delivery, whereas, titanium in 25 and 19mm tubing will run to £138 + delivery. The price for carbon fibre will be significantly higher because of the moulds, but we need leg patterns anyway for film special effects. Please note that this photograph is copyright © Jameson Hunter Ltd 2015. You will need permission from Jameson Hunter to be able to reproduce it.

JOINED AT THE HIP

There are hip, knee and ankle joints, but of those only the hip will be a full (not full, as in 360 x 360 degree rotation, there is no such thing, save in space) rotation joint. The steel balls of these joints are hard chrome plated. The balls run in bronze bearings that (in this case) are lubricated for life. We have made replacement servicing easy.

HIP JOINTS - Heavy duty spherical rod ends were to be used for the leg (hip) joints. These can take several tons each. We would have been using rose joints with a 14mm eye and coarse 14 x 2mm metric thread, but now these are just for the static display model.

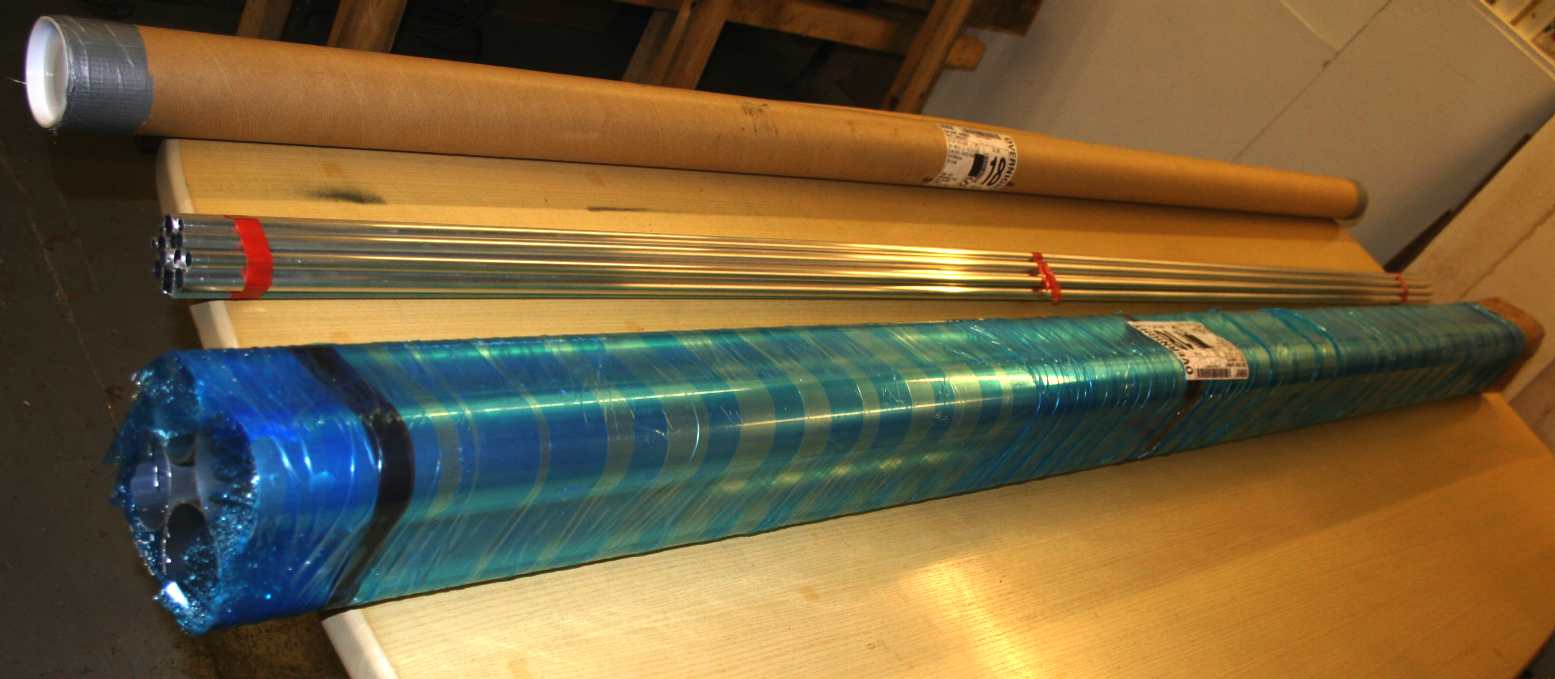

RAW MATERIALS - The aluminium tubing for our development legs arrived by TNT delivery on the 11th of January 2015. You will need to clear a large space to mark and cut the tubing to size. Not that there are four different diameter tubes. So be sure to mark the right length on the right diameter shaft and then be sure to mark the components. Or, you could just buy one of our kits and save all that hassle.

6063 ALLOY

You need to be careful when working with all metals. Aluminium is easy to cut and drill. But because it is softer, you need to take care not to deform the tubes - at least not until wargaming begins - and even then we'd hope paintball will mean duels to the death of a machine are avoided.

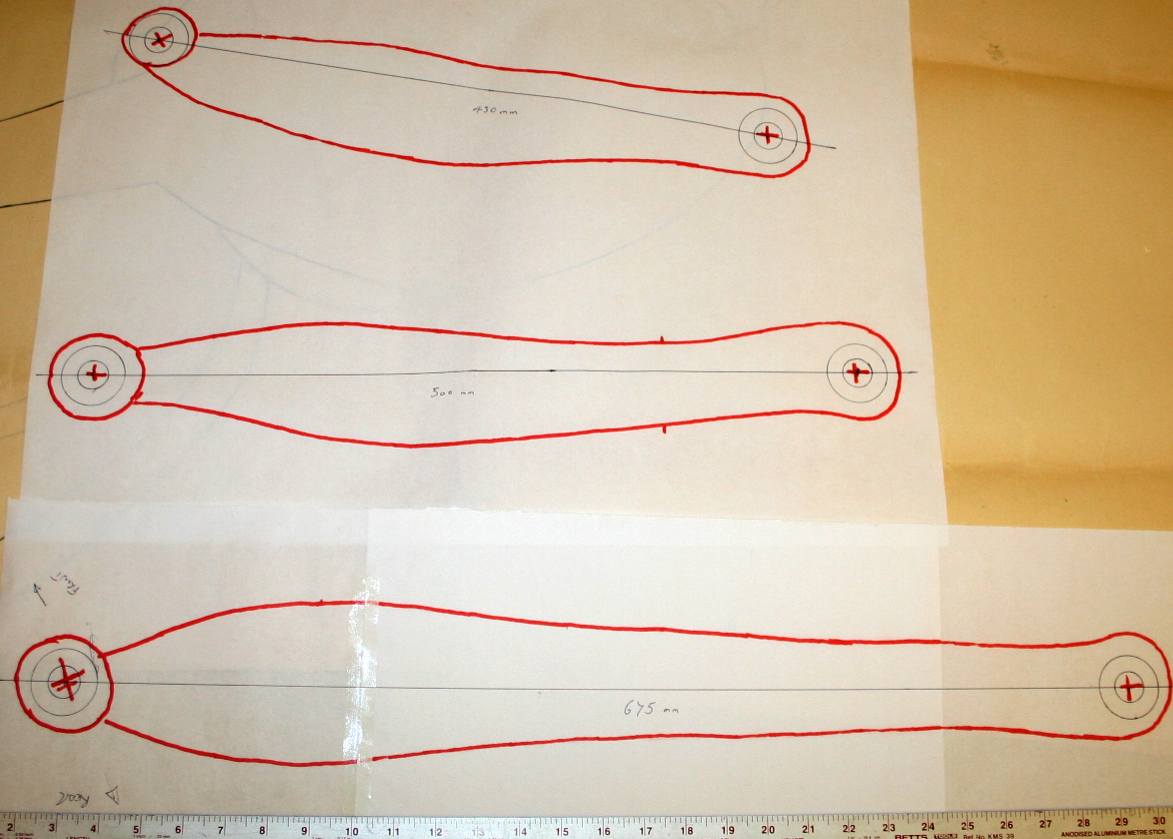

LEG DRAWINGS - Insects are complex animals. Note here that each thigh of the six legs is a different length. That means that the gearing of each leg will change for a smooth walking cycle - and then again the connecting rods will be different lengths and at different angles. Where's the ibuprofen when you need it? They are also handed, meaning that the left hind leg is a mirror image of the right hind leg, but they are not the same. That means making six separate leg moulds for the composite versions. We will be carving in wood at first, to make the master for the moulds.

GEOMETRY - Careful design of the leg is important if we are to avoid another actuator for the lower leg. We are thinking about a two-stage spring loaded system at the moment - with shock absorption. Amputee athletes use a similar system for high speed track events. Please note that this photograph and the subject drawing are copyright © Jameson Hunter Ltd 2015. You will need permission from Jameson Hunter to be able to reproduce it.

WOODEN LEGS - A tree had been cut down locally in the last 12 months so that the branches were fairly well seasoned. It seemed a shame to waste the wood, when we need to make 6 upper leg masters and 1 lower leg master. A master is the artwork that you use to make a GRP mould from. From the mould, you can make several sets of leg outers before re-conditioning the moulds. We used our trusty Bosch power plane - having serviced the bearings recently. This plane is over 20 years old and still going strong.

BARK REMOVAL - Branches were chosen that had a natural curve to match that of the real ant's legs. You could make the real legs from wood, being that structural softwood is stronger than steel, pound for pound. During World War II, fighter and bomber planes were made from wood because of the metals shortage. The problem with woodwork is the specialized skills needed from craftsmen.

ABOUT ALUMINIUM

Aluminium alloy 6063 is a versatile, medium strength alloy, commonly referred to as an architectural alloy. It is normally used in intricate extrusions. It has a good surface finish, high corrosion resistance, is readily suited to welding and can be easily anodised. Most commonly available as T6 temper, in the T4 condition it has good formability. 6063 is typically used in: Architectural applications, Extrusions, Ladders, Window frames, Doors, Shop fittings and Irrigation tubing. 6063 aluminium is also finding applications in hydro-formed tube for vehicle chassis.

Our preferred supplier is Aluminium Warehouse, which company offers a friendly, efficient service within the United Kingdom and simply superb packaging as you can see for yourselves in the pictures below.

PACKAGING - High quality aluminium demands high quality packaging. This was a larger order for a different project in June 2013, but the service and packing today is just as good and any issues are dealt with superbly. So, well done to Ally Warehouse.

IT'S THE LITTLE THINGS - From top left to bottom right, you can see how neat the ends of the cardboard tubing are taped - and it is strong duct tape. Undoing the ends we see that tape has been criss-crossed over a plastic end cap, to hold that firmly in place. Finally, when we pull out the white cap, the tubing is wrapped in a soft film that clings to itself and holds the tubes together inside the cardboard outer to stop the aluminium from scuffing. The end result is that the alloy tubing arrived in the workshop in good condition - and so put a huge smile on our faces. It is easy to forget all the trouble that so many people have to go to, to get a product to your front door on time. We're not even going to think about the mining and smelting operations involved. And the less said about city stockholders (speculators) the better.

ELECTRONICS

If you need to measure anything these days, you'll probably find that there is a bit of electronic kit to do the job for you. When we start cranking up the RPM, we are bound to want to know more about how the leg structure is coping. One way of measuring stretch and compression for any metal is to use a strain gauge.

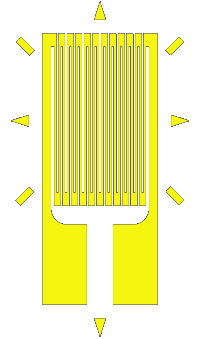

STRAIN GAUGES - A strain gauge (SG) is a device used to measure strain on an object.

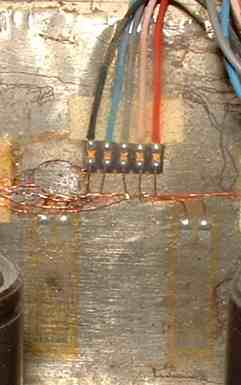

The most common type was invented by Edward E. Simmons and Arthur C. Ruge in 1938. This consists of a metal foil in a grid pattern, bonded to a flexible plastic film (polyimide insulator) that reinforces and insulates the foil from the item being measured. Typically, SGs are laser cut for accuracy. You can see a diagram above and a picture of the actual item as supplied by Radio Spares (RS). RS also do a neat amplifier that multiplies a signal (gain) x 1,000. The above assembly costs in the region of £60. You will need an amplifier and PCB + all the resistors and capacitors to assemble the above board, one for each leg - if dynamic testing - when you will also need an onboard computer to record the data, or a radio transmitter to send data.

The gauges (in multiples of four) are attached to the object to be monitored by a suitable adhesive, such as cyanoacrylate and the whole installation coated in epoxy resin. When an electrical wire (conductor) is stretched the decrease in diameter increases electrical resistance, measured in ohms. Conversely, if compressed, the increase in diameter decreases resistance. To increase the effective length of wire being stretched or compressed, a zig-zag pattern of parallel lines is used, producing a larger measurable change in resistance than would be observed with a single straight-line conductive wire - that would in any case be impractical. If four gauges are wired as per the diagram below and located on opposite sides of the object being measured, the resistance difference become much amplified. This circuit is known as a Wheatstone Bridge. Gauges are far more sensitive to strain in the direction of their grid. The markings outside the active area help to align the gauge during installation.

A Wheatstone bridge is an electrical circuit used to measure an unknown electrical resistance by balancing two legs of a bridge circuit, one leg of which includes the unknown component. The primary benefit of a Wheatstone bridge is its ability to provide extremely accurate measurements (in contrast with something like a simple voltage divider). Its operation is similar to the original potentiometer. It was invented by Samuel Hunter Christie in 1833 and improved and popularized by Sir Charles Wheatstone in 1843. That's a bit of electronic tech stuff, now back to the mechanics.

LINKS & REFERENCE

battle

Kits Kellycontroller 24v-48v 300a separately excited with regen Myskunkworks 200 amp PWM speed controller Electric scooter parts speed controllers 48 volt Buggies built for fun UK links http://www.electricscooterparts.com/speedcontrollers48volt.html http://kellycontroller.com/kdz48303gdv24v-48v300aseparately-excited-with-regen-p-1364.html http://myskunkworks.net/index.php?route=product/product&path=60&product_id=101 http://www.battlekits.com/ http://www.gngebike.com/apps/webstore/products/show/3019663 http://www.electricscooterparts.com/bicyclesprockets.html https://www.aldebaran.com/ http://www.softbank.jp/en/ http://electronics.howstuffworks.com/gadgets/other-gadgets/stun-gun.htm http://lynchmotors.co.uk/ http://www.nestle.co.uk/ http://www.mufg.jp/english/ http://www.maplin.co.uk/ http://www.royalmail.com/ http://www.bostondynamics.com/robot_bigdog.html http://uk.rs-online.com/web/c/automation-control-gear/sensors-transducers/strain-gauge-accessories/ http://zjmy-lu.en.made-in-china.com/product/YKNnjrEkZWVS/China-800W-36V-W-Bracket-Electric-Motor-Kit-W-Control-Box-Throttle-F-Scooter-My1020.html http://www.robots.nu/robot-animals/ http://buggies.builtforfun.co.uk/Links/index.php http://www.tnt.com/ http://www.knbefxgroup.com/

Tel:

01524 38 33 44 http://www.jandsfasteners.co.uk/

LEFT - Movie idea, lurking beneath the Antarctic ice is a discovery that scientists will die for. This story is now the subject of a low budget trailer to be produced mostly in the UK. The promoters are looking for backers. The UK will contribute 20% toward production costs. Roughly 60% of a low budget film may be pre-sold as distribution rights, leaving 20% finance to source. The deal is that investors recover 120% on their project stake within 12 months of shooting, with an income stream thereafter from networks and merchandising. Producers and directors please take note that there is a significant audience for well made movies of this genre. Look at what happened when they remade Godzilla. RIGHT - 1954 Warner Brothers movie poster for "Them." The plots are completely different, but the idea is similar, save that there is a degree more plausibility in the scale - and we hope, the ants to be used in the film.

A Sectasaur™ (thawed) - now on permanent display at Herstmonceux Museum, in Sussex, England.

ANTICS - ARDUINO - ARMOUR - ARTWORK - BIOLOGY - BLACK BOX - COMPUTERS - ELECTRONICS - ENERGY - FRAME - HEAD - JAWS - JIMMY WATSON - KITS - LEGS - MECHANICS - MOTORS - MOVIE - PHOTOGRAPHY - RASPBERRY Pi - R/C DRONE - SENTRY - SOFTWARE - SOUND PROOFING - SPEED - SUSPENSION - TAIL - WEAPONS - WARGAMING

DINOSAURS - DOLPHINS - HUMANOIDS - RAYS - SHARKS - WHALES

ARDUINO - ARM HOLDINGS - BEAGLEBOARD - MBED - PCBS - PICAXE - RASPBERRY PI

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This website is Copyright © 2024 Bluebird Marine Systems Limited. The names Bluebird™, Bluefish™, Miss Ocean™, SeaNet™, SeaVax™ are trademarks. All other trademarks are hereby acknowledged. The design of the Robot Ant on this page is design copyright © December 15 2015, all rights reserved - Jameson Hunter Ltd. IMPORTANT NOTE: Under no circumstances may our products, or those of Jameson Hunter Ltd, be used by any military or law enforcement organization, for any warlike, combat, or peacekeeping crowd control purposes. Anyone purchasing one of these units will be required to sign a binding undertaking (Deed) to that effect. Any unit found to have been purchased by proxy, will be confiscated, along with civil remedy in respect of breach of contract, that all parties in the chain will be vicariously liable for - to include damages for vehicles developed from our designs without our consent - and possible fraud issue from the deception. In addition to copyright theft, the law of passing-off applies.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||